├── BOM.md

├── Firmware-1.24

├── .gitignore

├── .travis.yml

├── BOM.md

├── CODE_OF_CONDUCT.md

├── Documentation

│ ├── Download Firmware.jpg

│ ├── Download IDE.jpg

│ ├── How To Contribute Pictures

│ │ ├── Clone.png

│ │ ├── Clone2.png

│ │ ├── Clone3.png

│ │ ├── Commit.png

│ │ ├── EditingFile.png

│ │ ├── Fork.jpg

│ │ ├── GithubHome.jpg

│ │ ├── GithubWelcome.jpg

│ │ ├── PR0.png

│ │ ├── PR1.png

│ │ ├── PR2.png

│ │ ├── PR3.png

│ │ └── Push Origin.png

│ ├── Open Firmware.jpg

│ ├── Select Board.jpg

│ ├── Select COM Port.jpg

│ ├── Upload.jpg

│ └── posErrorAlarm

│ │ ├── alarm.PNG

│ │ └── alarmSetting.PNG

├── INSTRUCTIONS.md

├── LICENSE

├── README.md

├── ROBOT.md

├── cnc_ctrl_v1

│ ├── Axis.cpp

│ ├── Axis.h

│ ├── Config.h

│ ├── Encoder.cpp

│ ├── Encoder.h

│ ├── GCode.cpp

│ ├── GCode.h

│ ├── Kinematics.cpp

│ ├── Kinematics.h

│ ├── Maslow.h

│ ├── Motion.cpp

│ ├── Motion.h

│ ├── Motor.cpp

│ ├── Motor.h

│ ├── MotorGearboxEncoder.cpp

│ ├── MotorGearboxEncoder.h

│ ├── NutsAndBolts.cpp

│ ├── NutsAndBolts.h

│ ├── PID_v1.cpp

│ ├── PID_v1.h

│ ├── Probe.cpp

│ ├── Probe.h

│ ├── Report.cpp

│ ├── Report.h

│ ├── RingBuffer.cpp

│ ├── RingBuffer.h

│ ├── Settings.cpp

│ ├── Settings.h

│ ├── SimavrSerial.cpp

│ ├── SimavrSerial.h

│ ├── Spindle.cpp

│ ├── Spindle.h

│ ├── System.cpp

│ ├── System.h

│ ├── Testing.cpp

│ ├── Testing.h

│ ├── TimerOne.cpp

│ ├── TimerOne.h

│ ├── cnc_ctrl_v1.ino

│ └── utility

│ │ ├── direct_pin_read.h

│ │ ├── interrupt_config.h

│ │ └── interrupt_pins.h

├── guestBook.txt

├── mainpicture.jpg

├── platformio.ini

└── platformio

│ ├── simavr_env.py

│ └── teensy_env.py

├── INSTRUCTIONS.md

├── README.md

├── ROBOT.md

├── Ring_Kit.jpg

├── mainpicture.jpg

└── usrinput.txt

/BOM.md:

--------------------------------------------------------------------------------

1 | Head over to [MakerMade](http://www.makermade.com/shop) to order.

2 |

--------------------------------------------------------------------------------

/Firmware-1.24/.gitignore:

--------------------------------------------------------------------------------

1 | .pioenvs

2 | .piolibdeps

3 | .clang_complete

4 | .gcc-flags.json

5 | lib/readme.txt

6 | cnc_ctrl_v1/.DS_Store

7 | cnc_ctrl_v1/.DS_Store

8 | cnc_ctrl_v1/.DS_Store

9 | .DS_Store

10 | **/.DS_Store

11 | .vscode/

12 | .vscode/c_cpp_properties.json

13 | .vscode/launch.json

14 | simduino_atmega2560_flash.bin

15 | simduino

16 | .vscode/*.db

17 | obj-x86_64-apple-darwin17.4.0

18 |

--------------------------------------------------------------------------------

/Firmware-1.24/.travis.yml:

--------------------------------------------------------------------------------

1 | # Continuous Integration (CI) is the practice, in software

2 | # engineering, of merging all developer working copies with a shared mainline

3 | # several times a day < http://docs.platformio.org/page/ci/index.html >

4 | #

5 | # Documentation:

6 | #

7 | # * Travis CI Embedded Builds with PlatformIO

8 | # < https://docs.travis-ci.com/user/integration/platformio/ >

9 | #

10 | # * PlatformIO integration with Travis CI

11 | # < http://docs.platformio.org/page/ci/travis.html >

12 | #

13 | # * User Guide for `platformio ci` command

14 | # < http://docs.platformio.org/page/userguide/cmd_ci.html >

15 | #

16 | #

17 | # Please choice one of the following templates (proposed below) and uncomment

18 | # it (remove "# " before each line) or use own configuration according to the

19 | # Travis CI documentation (see above).

20 | #

21 |

22 |

23 | #

24 | # Template #1: General project. Test it using existing `platformio.ini`.

25 | #

26 |

27 | language: python

28 | python:

29 | - "2.7"

30 |

31 | install:

32 | - pip install -U platformio

33 |

34 | script:

35 | - platformio run

36 |

--------------------------------------------------------------------------------

/Firmware-1.24/BOM.md:

--------------------------------------------------------------------------------

1 | The firmware is and always will be free!

2 |

3 | You can download the latest version [here](https://github.com/MaslowCNC/Firmware/releases)

4 |

--------------------------------------------------------------------------------

/Firmware-1.24/CODE_OF_CONDUCT.md:

--------------------------------------------------------------------------------

1 | # Contributor Covenant Code of Conduct

2 |

3 | ## Our Pledge

4 |

5 | In the interest of fostering an open and welcoming environment, we as contributors and maintainers pledge to making participation in our project and our community a harassment-free experience for everyone, regardless of age, body size, disability, ethnicity, gender identity and expression, level of experience, nationality, personal appearance, race, religion, or sexual identity and orientation.

6 |

7 | ## Our Standards

8 |

9 | Examples of behavior that contributes to creating a positive environment include:

10 |

11 | * Using welcoming and inclusive language

12 | * Being respectful of differing viewpoints and experiences

13 | * Gracefully accepting constructive criticism

14 | * Focusing on what is best for the community

15 | * Showing empathy towards other community members

16 |

17 | Examples of unacceptable behavior by participants include:

18 |

19 | * The use of sexualized language or imagery and unwelcome sexual attention or advances

20 | * Trolling, insulting/derogatory comments, and personal or political attacks

21 | * Public or private harassment

22 | * Publishing others' private information, such as a physical or electronic address, without explicit permission

23 | * Other conduct which could reasonably be considered inappropriate in a professional setting

24 |

25 | ## Our Responsibilities

26 |

27 | Project maintainers are responsible for clarifying the standards of acceptable behavior and are expected to take appropriate and fair corrective action in response to any instances of unacceptable behavior.

28 |

29 | Project maintainers have the right and responsibility to remove, edit, or reject comments, commits, code, wiki edits, issues, and other contributions that are not aligned to this Code of Conduct, or to ban temporarily or permanently any contributor for other behaviors that they deem inappropriate, threatening, offensive, or harmful.

30 |

31 | ## Scope

32 |

33 | This Code of Conduct applies both within project spaces and in public spaces when an individual is representing the project or its community. Examples of representing a project or community include using an official project e-mail address, posting via an official social media account, or acting as an appointed representative at an online or offline event. Representation of a project may be further defined and clarified by project maintainers.

34 |

35 | ## Enforcement

36 |

37 | Instances of abusive, harassing, or otherwise unacceptable behavior may be reported by contacting the project team at info@maslowcnc.com. The project team will review and investigate all complaints, and will respond in a way that it deems appropriate to the circumstances. The project team is obligated to maintain confidentiality with regard to the reporter of an incident. Further details of specific enforcement policies may be posted separately.

38 |

39 | Project maintainers who do not follow or enforce the Code of Conduct in good faith may face temporary or permanent repercussions as determined by other members of the project's leadership.

40 |

41 | ## Attribution

42 |

43 | This Code of Conduct is adapted from the [Contributor Covenant][homepage], version 1.4, available at [http://contributor-covenant.org/version/1/4][version]

44 |

45 | [homepage]: http://contributor-covenant.org

46 | [version]: http://contributor-covenant.org/version/1/4/

47 |

--------------------------------------------------------------------------------

/Firmware-1.24/Documentation/Download Firmware.jpg:

--------------------------------------------------------------------------------

https://raw.githubusercontent.com/MaslowCommunityGarden/CNC-Compression-Bit/fcf2d4d49632e6302f3956f970cd157669506163/Firmware-1.24/Documentation/Download Firmware.jpg

--------------------------------------------------------------------------------

/Firmware-1.24/Documentation/Download IDE.jpg:

--------------------------------------------------------------------------------

https://raw.githubusercontent.com/MaslowCommunityGarden/CNC-Compression-Bit/fcf2d4d49632e6302f3956f970cd157669506163/Firmware-1.24/Documentation/Download IDE.jpg

--------------------------------------------------------------------------------

/Firmware-1.24/Documentation/How To Contribute Pictures/Clone.png:

--------------------------------------------------------------------------------

https://raw.githubusercontent.com/MaslowCommunityGarden/CNC-Compression-Bit/fcf2d4d49632e6302f3956f970cd157669506163/Firmware-1.24/Documentation/How To Contribute Pictures/Clone.png

--------------------------------------------------------------------------------

/Firmware-1.24/Documentation/How To Contribute Pictures/Clone2.png:

--------------------------------------------------------------------------------

https://raw.githubusercontent.com/MaslowCommunityGarden/CNC-Compression-Bit/fcf2d4d49632e6302f3956f970cd157669506163/Firmware-1.24/Documentation/How To Contribute Pictures/Clone2.png

--------------------------------------------------------------------------------

/Firmware-1.24/Documentation/How To Contribute Pictures/Clone3.png:

--------------------------------------------------------------------------------

https://raw.githubusercontent.com/MaslowCommunityGarden/CNC-Compression-Bit/fcf2d4d49632e6302f3956f970cd157669506163/Firmware-1.24/Documentation/How To Contribute Pictures/Clone3.png

--------------------------------------------------------------------------------

/Firmware-1.24/Documentation/How To Contribute Pictures/Commit.png:

--------------------------------------------------------------------------------

https://raw.githubusercontent.com/MaslowCommunityGarden/CNC-Compression-Bit/fcf2d4d49632e6302f3956f970cd157669506163/Firmware-1.24/Documentation/How To Contribute Pictures/Commit.png

--------------------------------------------------------------------------------

/Firmware-1.24/Documentation/How To Contribute Pictures/EditingFile.png:

--------------------------------------------------------------------------------

https://raw.githubusercontent.com/MaslowCommunityGarden/CNC-Compression-Bit/fcf2d4d49632e6302f3956f970cd157669506163/Firmware-1.24/Documentation/How To Contribute Pictures/EditingFile.png

--------------------------------------------------------------------------------

/Firmware-1.24/Documentation/How To Contribute Pictures/Fork.jpg:

--------------------------------------------------------------------------------

https://raw.githubusercontent.com/MaslowCommunityGarden/CNC-Compression-Bit/fcf2d4d49632e6302f3956f970cd157669506163/Firmware-1.24/Documentation/How To Contribute Pictures/Fork.jpg

--------------------------------------------------------------------------------

/Firmware-1.24/Documentation/How To Contribute Pictures/GithubHome.jpg:

--------------------------------------------------------------------------------

https://raw.githubusercontent.com/MaslowCommunityGarden/CNC-Compression-Bit/fcf2d4d49632e6302f3956f970cd157669506163/Firmware-1.24/Documentation/How To Contribute Pictures/GithubHome.jpg

--------------------------------------------------------------------------------

/Firmware-1.24/Documentation/How To Contribute Pictures/GithubWelcome.jpg:

--------------------------------------------------------------------------------

https://raw.githubusercontent.com/MaslowCommunityGarden/CNC-Compression-Bit/fcf2d4d49632e6302f3956f970cd157669506163/Firmware-1.24/Documentation/How To Contribute Pictures/GithubWelcome.jpg

--------------------------------------------------------------------------------

/Firmware-1.24/Documentation/How To Contribute Pictures/PR0.png:

--------------------------------------------------------------------------------

https://raw.githubusercontent.com/MaslowCommunityGarden/CNC-Compression-Bit/fcf2d4d49632e6302f3956f970cd157669506163/Firmware-1.24/Documentation/How To Contribute Pictures/PR0.png

--------------------------------------------------------------------------------

/Firmware-1.24/Documentation/How To Contribute Pictures/PR1.png:

--------------------------------------------------------------------------------

https://raw.githubusercontent.com/MaslowCommunityGarden/CNC-Compression-Bit/fcf2d4d49632e6302f3956f970cd157669506163/Firmware-1.24/Documentation/How To Contribute Pictures/PR1.png

--------------------------------------------------------------------------------

/Firmware-1.24/Documentation/How To Contribute Pictures/PR2.png:

--------------------------------------------------------------------------------

https://raw.githubusercontent.com/MaslowCommunityGarden/CNC-Compression-Bit/fcf2d4d49632e6302f3956f970cd157669506163/Firmware-1.24/Documentation/How To Contribute Pictures/PR2.png

--------------------------------------------------------------------------------

/Firmware-1.24/Documentation/How To Contribute Pictures/PR3.png:

--------------------------------------------------------------------------------

https://raw.githubusercontent.com/MaslowCommunityGarden/CNC-Compression-Bit/fcf2d4d49632e6302f3956f970cd157669506163/Firmware-1.24/Documentation/How To Contribute Pictures/PR3.png

--------------------------------------------------------------------------------

/Firmware-1.24/Documentation/How To Contribute Pictures/Push Origin.png:

--------------------------------------------------------------------------------

https://raw.githubusercontent.com/MaslowCommunityGarden/CNC-Compression-Bit/fcf2d4d49632e6302f3956f970cd157669506163/Firmware-1.24/Documentation/How To Contribute Pictures/Push Origin.png

--------------------------------------------------------------------------------

/Firmware-1.24/Documentation/Open Firmware.jpg:

--------------------------------------------------------------------------------

https://raw.githubusercontent.com/MaslowCommunityGarden/CNC-Compression-Bit/fcf2d4d49632e6302f3956f970cd157669506163/Firmware-1.24/Documentation/Open Firmware.jpg

--------------------------------------------------------------------------------

/Firmware-1.24/Documentation/Select Board.jpg:

--------------------------------------------------------------------------------

https://raw.githubusercontent.com/MaslowCommunityGarden/CNC-Compression-Bit/fcf2d4d49632e6302f3956f970cd157669506163/Firmware-1.24/Documentation/Select Board.jpg

--------------------------------------------------------------------------------

/Firmware-1.24/Documentation/Select COM Port.jpg:

--------------------------------------------------------------------------------

https://raw.githubusercontent.com/MaslowCommunityGarden/CNC-Compression-Bit/fcf2d4d49632e6302f3956f970cd157669506163/Firmware-1.24/Documentation/Select COM Port.jpg

--------------------------------------------------------------------------------

/Firmware-1.24/Documentation/Upload.jpg:

--------------------------------------------------------------------------------

https://raw.githubusercontent.com/MaslowCommunityGarden/CNC-Compression-Bit/fcf2d4d49632e6302f3956f970cd157669506163/Firmware-1.24/Documentation/Upload.jpg

--------------------------------------------------------------------------------

/Firmware-1.24/Documentation/posErrorAlarm/alarm.PNG:

--------------------------------------------------------------------------------

https://raw.githubusercontent.com/MaslowCommunityGarden/CNC-Compression-Bit/fcf2d4d49632e6302f3956f970cd157669506163/Firmware-1.24/Documentation/posErrorAlarm/alarm.PNG

--------------------------------------------------------------------------------

/Firmware-1.24/Documentation/posErrorAlarm/alarmSetting.PNG:

--------------------------------------------------------------------------------

https://raw.githubusercontent.com/MaslowCommunityGarden/CNC-Compression-Bit/fcf2d4d49632e6302f3956f970cd157669506163/Firmware-1.24/Documentation/posErrorAlarm/alarmSetting.PNG

--------------------------------------------------------------------------------

/Firmware-1.24/INSTRUCTIONS.md:

--------------------------------------------------------------------------------

1 |

2 |

3 | # Maslow Firmware Setup

4 |

5 | Installing new firmware on your machine is important. We come out with a new firmware version every other week so be prepared to do this regularly. This process will also install the proper drivers to connect to your Arduino on some older computers so if you have trouble connecting it can be helpful to do this process on the same computer you will control the machine with.

6 |

7 | ### Step 1: Connect Your Arduino

8 | Connect your Arduino to your computer using the provided USB cable.

9 |

10 | ### Step 2: Download The Arduino IDE

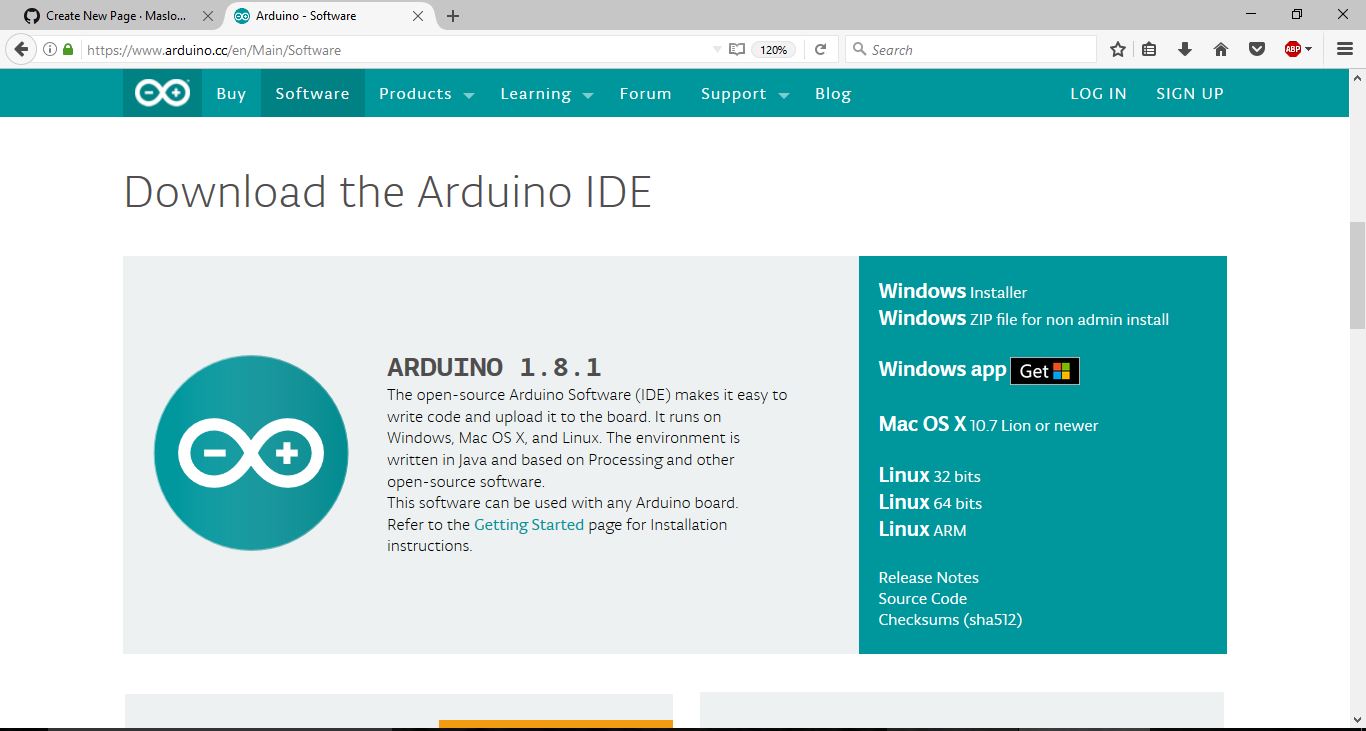

11 | Download and install the last Arduino IDE from [https://www.arduino.cc/en/Main/Software](https://www.arduino.cc/en/Main/Software). Older versions of Arduino IDE have problems with libraries when compiling the firmware, so make sure you have the latest version.

12 |

13 | Note - For Windows there are three options: "Windows Installer", "Windows Zip", and "Windows App".

14 | Some users have reported problems with the "Windows App" version.

15 |

16 |

17 | ### Step 3: Download The Latest Maslow Firmware

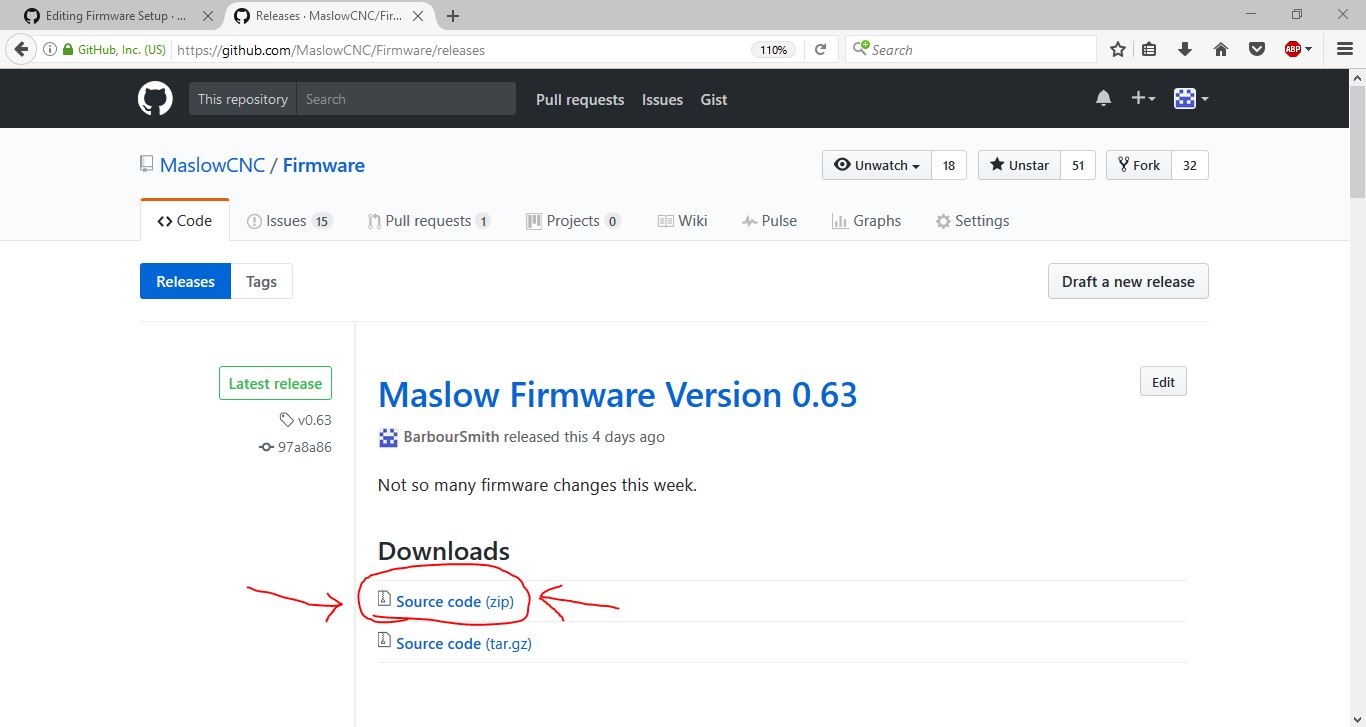

18 | You can do this at http://github.com/MaslowCNC/Firmware/releases/ Click the zip file for the most recent release to download it. Extract the files from the zip folder.

19 |

20 |

21 | ### Step 4: Open Firmware

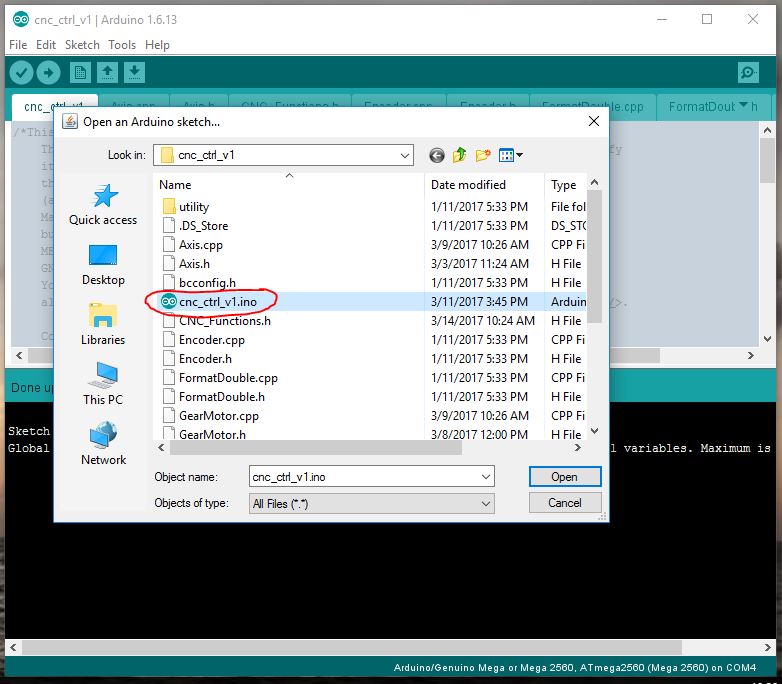

22 | Click **File -> Open** and then open the firmware by selecting cnc_ctrl_v1.ino

23 |

24 |

25 | ### Step 5: Select The Board Type

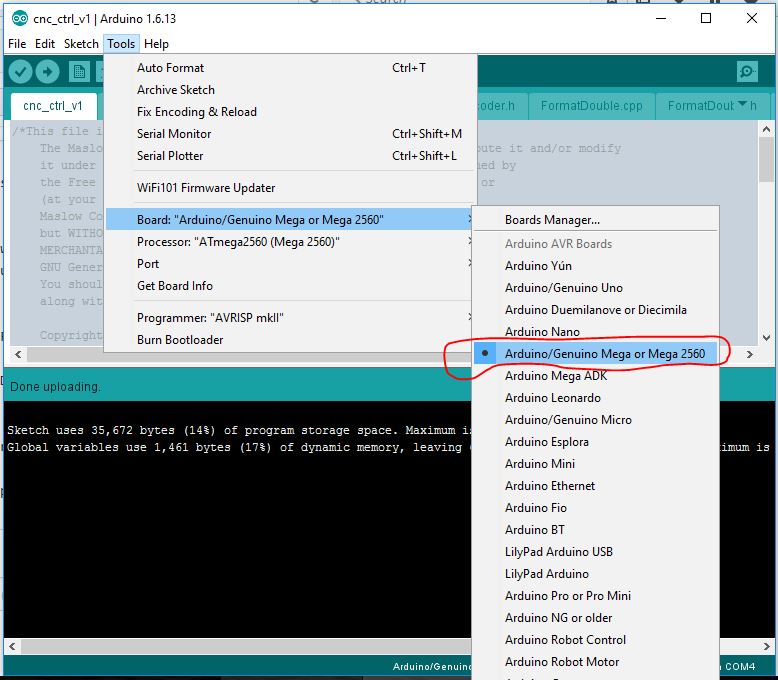

26 | Select the board type by clicking **Tools -> Board -> Arduino/Genuino Mega or Mega 2560**

27 |

28 |

29 | ### Step 6: Select The Serial Port

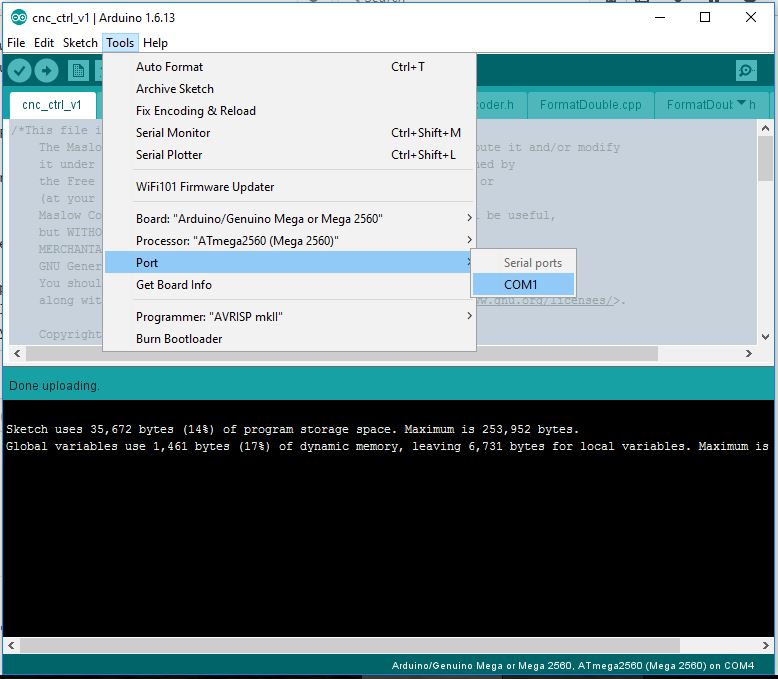

30 | Select the correct port to connect to by clicking **Tools -> Port -> Your Port**. On Windows this will be something like COM3, on Mac and Linux computers it will be something like dev/tty/. You can find the right one by plugging and unplugging your Arduino compatible board and checking which option disappears.

31 |

32 |

33 | ### Step 7: Upload The Firmware

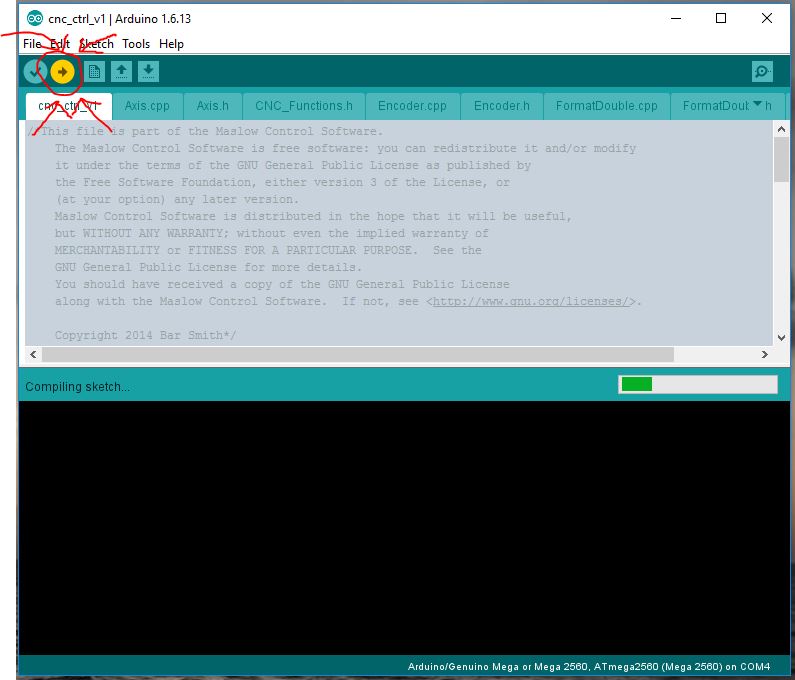

34 | Upload the newest firmware to your machine by clicking the upload button in the top left corner. The arrow looks disabled until you hover over it! _Linux users_: if you are getting timeout or permissions errors, you may need to add your username to the `dialout` group and then logout and back in. [Instructions here.](https://askubuntu.com/questions/112568/how-do-i-allow-a-non-default-user-to-use-serial-device-ttyusb0)

35 |

36 |

37 | ### Step 8: Finish

38 | You are now running the latest firmware. *Great Job!* Make sure you close the Arduino IDE before proceeding.

39 |

40 | ### Step 9: Proceed

41 | You have finished setting up the Maslow firmware. Proceed to the [next step](http://maslowcommunitygarden.org/GroundControl.html?instructions=true) to install Ground Control on your OS.

42 |

--------------------------------------------------------------------------------

/Firmware-1.24/LICENSE:

--------------------------------------------------------------------------------

https://raw.githubusercontent.com/MaslowCommunityGarden/CNC-Compression-Bit/fcf2d4d49632e6302f3956f970cd157669506163/Firmware-1.24/LICENSE

--------------------------------------------------------------------------------

/Firmware-1.24/README.md:

--------------------------------------------------------------------------------

1 | # Maslow Firmware

2 |

3 | This is the firmware which controls the Maslow CNC machine

4 |

5 | [](https://travis-ci.org/MaslowCNC/Firmware)

6 |

7 | This is the firmware for the Maslow CNC Router

8 |

9 |

10 | ## Steps to setup the Firmware development environment

11 |

12 | First clone the Firmware repository, then install and setup the IDE of your choice.

13 |

14 | ### Using Arduino IDE

15 | 1. Download [Arduino IDE](https://www.arduino.cc/en/main/software) 1.8.1 or higher

16 | 2. Install Arduino IDE and run Arduino IDE

17 | 3. Navigate menus: File, Open

18 | 4. In the file chooser navigate to the cloned repository and choose the "cnc_ctrl_v1.ino" file to open

19 | 5. Navigate menu: Tools, Board, change to "Arduino/Genuino Mega or Mega 2560"

20 | 6. Navigate menu: Sketch -> Upload

21 |

22 | This should compile the project without errors, and possibly some warnings.

23 |

24 | ### Using PlatformIO

25 | 1. Download package for [Atom](https://atom.io/)

26 | 2. Follow directions for [installing PlatformIO within Atom](http://docs.platformio.org/en/latest/ide/atom.html#ide-installation)

27 | 3. Within Atom navigate menus: PlatformIO, Open Project

28 | 4. Select "Firmware" directory

29 | 5. Click "Open Firmware"

30 |

31 | ### Using Eclipse Neon C/C++ with Sloeber plugin

32 |

33 | 1. Download [Eclipse C/C++](https://eclipse.org/downloads/) Neon or higher

34 | 2. Install Eclipse C/C++ and run Eclipse

35 | 3. Install Sloeber Arduino plugin

36 | * Navigate menus: Help, Install New Software...

37 | * Copy this URL in the "Work With" field: http://eclipse.baeyens.it/update/V4/stable

38 | * Select "Add" button

39 | * Select "Sloeber Arduino IDE" check box

40 | * Select "Finish" button

41 | * Accept defaults and accept licenses, the plugin will restart Eclipse, and configure the plugin

42 | 4. Change to Arduino perspective, navigate menus: Window, Perspective, Open Perspective, Other...

43 | * Choose the "Arduino" perspective and select "Ok" button

44 | 5. Create an Arduino project

45 | * Navigate menus: File, New, New Arduino Sketch

46 | * Project Name: cnc_ctrl_v1

47 | * Select "Next" button

48 | * Select appropriate item from "Platform folder" drop down listing

49 | * Select Board: Arduino/Genuino Mega or Mega 2560

50 | * Select Upload Protocol: Default

51 | * Select Processor: ATmega2560 (Mega 2560)

52 | * Select "Finish" button

53 | 6. Import project source code

54 | * Select project folder, navigate menus: File, Import...

55 | * Expand "General" and select "File system"

56 | * Select "Next" button

57 | * Select the "Browse" button to select the source location (location of the cloned repository cnc_ctrl_v1 directory)

58 | * Select whole source directory in the left pane

59 | * Open Advanced Settings by klicking on "Advanced>>" button

60 | * Select 'Create Links in Workspace' and 'Create virtual folders' leave other settings untouched

61 | * Select 'Finish' button

62 | * Eclipse asks if overwriting the original cnc_ctrl_v1.ino file is ok. Confirm with 'yes'.

63 | 7. Update eclipse project include paths

64 | * Select the project folder in the project explorer and click Project->Properties in the menu.

65 | * In the Project properties left Pane select C/C++ Build->Settings

66 | * In the right Pane select the 'Tool Settings' Tab and add the path to the source location to the include paths of all compilers/linkers of the toolchain.

67 | * The last two steps may differ between toolchains.

68 |

69 |

70 | ### Using NotePad++ in Conjunction with the Arduino IDE

71 | 1. Download NotePad++ (Windows only) [link](https://notepad-plus-plus.org/)

72 | 2. Download the Arduino IDE [link](https://www.arduino.cc/en/main/software)

73 | 3. Set that you would like use an external editor from within the Arduino IDE by clicking File -> Preferences -> Use External Editor

74 | *The Arduino editor will no longer allow you to edit the files, but instead will only work to compile and upload your code.

75 | *The code can be edited from within NotePad++

76 | *This method can be used on other platforms with editing programs other than NP++

77 |

78 |

--------------------------------------------------------------------------------

/Firmware-1.24/ROBOT.md:

--------------------------------------------------------------------------------

1 | {

2 | "ModerationLevel": "communityManaged",

3 | "Facilitator": "barboursmith",

4 | "DownloadTarget": "/releases",

5 | "Category": "maslow"

6 | }

7 |

--------------------------------------------------------------------------------

/Firmware-1.24/cnc_ctrl_v1/Axis.cpp:

--------------------------------------------------------------------------------

1 | /*This file is part of the Maslow Control Software.

2 |

3 | The Maslow Control Software is free software: you can redistribute it and/or modify

4 | it under the terms of the GNU General Public License as published by

5 | the Free Software Foundation, either version 3 of the License, or

6 | (at your option) any later version.

7 |

8 | Maslow Control Software is distributed in the hope that it will be useful,

9 | but WITHOUT ANY WARRANTY; without even the implied warranty of

10 | MERCHANTABILITY or FITNESS FOR A PARTICULAR PURPOSE. See the

11 | GNU General Public License for more details.

12 |

13 | You should have received a copy of the GNU General Public License

14 | along with the Maslow Control Software. If not, see .

15 |

16 | Copyright 2014-2017 Bar Smith*/

17 |

18 |

19 | #include "Maslow.h"

20 |

21 | void Axis::setup(const int& pwmPin, const int& directionPin1, const int& directionPin2, const int& encoderPin1, const int& encoderPin2, const char& axisName, const unsigned long& loopInterval)

22 | {

23 | // I don't really like this, but I don't know how else to initialize a pointer to a value

24 | float zero = 0.0;

25 | float one = 1.0;

26 | _Kp = _Ki = _Kd = &zero;

27 |

28 | motorGearboxEncoder.setup(pwmPin, directionPin1, directionPin2, encoderPin1, encoderPin2, loopInterval);

29 | _pidController.setup(&_pidInput, &_pidOutput, &_pidSetpoint, _Kp, _Ki, _Kd, &one, REVERSE);

30 |

31 | //initialize variables

32 | _axisName = axisName;

33 |

34 | initializePID(loopInterval);

35 |

36 | motorGearboxEncoder.setName(&_axisName);

37 | }

38 |

39 | void Axis::initializePID(const unsigned long& loopInterval){

40 | _pidController.SetMode(AUTOMATIC);

41 | _pidController.SetOutputLimits(-20, 20);

42 | _pidController.SetSampleTime( loopInterval / 1000);

43 | }

44 |

45 | void Axis::write(const float& targetPosition){

46 | _timeLastMoved = millis();

47 | _pidSetpoint = targetPosition/ *_mmPerRotation;

48 | return;

49 | }

50 |

51 | float Axis::read(){

52 | //returns the true axis position

53 |

54 | return (motorGearboxEncoder.encoder.read()/ *_encoderSteps) * *_mmPerRotation;

55 |

56 | }

57 |

58 | float Axis::setpoint(){

59 | return _pidSetpoint * *_mmPerRotation;

60 | }

61 |

62 | void Axis::set(const float& newAxisPosition){

63 |

64 | //reset everything to the new value

65 | _pidSetpoint = newAxisPosition/ *_mmPerRotation;

66 | motorGearboxEncoder.encoder.write((newAxisPosition * *_encoderSteps)/ *_mmPerRotation);

67 |

68 | }

69 |

70 | long Axis::steps(){

71 | /*

72 | Returns the number of steps reported by the encoder

73 | */

74 | return motorGearboxEncoder.encoder.read();

75 | }

76 |

77 | void Axis::setSteps(const long& steps){

78 |

79 | //reset everything to the new value

80 | _pidSetpoint = steps/ *_encoderSteps;

81 | motorGearboxEncoder.encoder.write(steps);

82 |

83 | }

84 |

85 | void Axis::computePID(){

86 |

87 | #ifdef FAKE_SERVO

88 | if (motorGearboxEncoder.motor.attached()){

89 | // Adds up to 10% error just to simulate servo noise

90 | double rpm = (-1 * _pidOutput) * random(90, 110) / 100;

91 | unsigned long steps = motorGearboxEncoder.encoder.read() + round( rpm * *_encoderSteps * LOOPINTERVAL)/(60 * 1000000);

92 | motorGearboxEncoder.encoder.write(steps);

93 | }

94 | #endif

95 |

96 | if (_disableAxisForTesting || !motorGearboxEncoder.motor.attached()){

97 | return;

98 | }

99 |

100 | _pidInput = motorGearboxEncoder.encoder.read()/ *_encoderSteps;

101 |

102 | if (_pidController.Compute()){

103 | // Only write output if the PID calculation was performed

104 | motorGearboxEncoder.write(_pidOutput);

105 | }

106 |

107 | motorGearboxEncoder.computePID();

108 |

109 | }

110 |

111 | void Axis::disablePositionPID(){

112 |

113 | _pidController.SetMode(MANUAL);

114 |

115 | }

116 |

117 | void Axis::enablePositionPID(){

118 |

119 | _pidController.SetMode(AUTOMATIC);

120 |

121 | }

122 |

123 | void Axis::setPIDValues(float* KpPos, float* KiPos, float* KdPos, float* propWeight, float* KpV, float* KiV, float* KdV, float* propWeightV){

124 | /*

125 |

126 | Sets the positional PID values for the axis

127 |

128 | */

129 | _Kp = KpPos;

130 | _Ki = KiPos;

131 | _Kd = KdPos;

132 |

133 | _pidController.SetTunings(_Kp, _Ki, _Kd, propWeight);

134 |

135 | motorGearboxEncoder.setPIDValues(KpV, KiV, KdV, propWeightV);

136 | }

137 |

138 | String Axis::getPIDString(){

139 | /*

140 |

141 | Get PID tuning values

142 |

143 | */

144 | String PIDString = "Kp=";

145 | return PIDString + *_Kp + ",Ki=" + *_Ki + ",Kd=" + *_Kd;

146 | }

147 |

148 | void Axis::setPIDAggressiveness(float aggressiveness){

149 | /*

150 |

151 | The setPIDAggressiveness() function sets the aggressiveness of the PID controller to

152 | compensate for a change in the load on the motor.

153 |

154 | */

155 |

156 | motorGearboxEncoder.setPIDAggressiveness(aggressiveness);

157 | }

158 |

159 | float Axis::error(){

160 |

161 | float encoderErr = (motorGearboxEncoder.encoder.read()/ *_encoderSteps) - _pidSetpoint;

162 |

163 | return encoderErr * *_mmPerRotation;

164 | }

165 |

166 | void Axis::changePitch(float *newPitch){

167 | /*

168 | Reassign the distance moved per-rotation for the axis.

169 | */

170 | _mmPerRotation = newPitch;

171 | }

172 |

173 | float Axis::getPitch(){

174 | /*

175 | Returns the distance moved per-rotation for the axis.

176 | */

177 | return *_mmPerRotation;

178 | }

179 |

180 | void Axis::changeEncoderResolution(float *newResolution){

181 | /*

182 | Reassign the encoder resolution for the axis.

183 | */

184 | _encoderSteps = newResolution;

185 |

186 | //push to the gearbox for calculating RPM

187 | motorGearboxEncoder.setEncoderResolution(*newResolution);

188 |

189 | }

190 |

191 | int Axis::detach(){

192 |

193 | motorGearboxEncoder.motor.detach();

194 |

195 | return 1;

196 | }

197 |

198 | int Axis::attach(){

199 | motorGearboxEncoder.motor.attach();

200 | return 1;

201 | }

202 |

203 | bool Axis::attached(){

204 | /*

205 |

206 | Returns true if the axis is attached, false if it is not.

207 |

208 | */

209 |

210 | return motorGearboxEncoder.motor.attached();

211 | }

212 |

213 | void Axis::detachIfIdle(){

214 | /*

215 | Detaches the axis, turning off the motor and PID control, if it has been

216 | stationary for more than axisDetachTime

217 | */

218 | if (millis() - _timeLastMoved > sysSettings.axisDetachTime){

219 | detach();

220 | }

221 |

222 | }

223 |

224 | void Axis::endMove(const float& finalTarget){

225 |

226 | _timeLastMoved = millis();

227 | _pidSetpoint = finalTarget/ *_mmPerRotation;

228 |

229 | }

230 |

231 | void Axis::stop(){

232 | /*

233 |

234 | Immediately stop the axis where it is, not where it should be

235 |

236 | */

237 |

238 | _timeLastMoved = millis();

239 | _pidSetpoint = read()/ *_mmPerRotation;

240 |

241 | }

242 |

243 | void Axis::test(){

244 | /*

245 | Test the axis by directly commanding the motor and observing if the encoder moves

246 | */

247 |

248 | Serial.print(F("Testing "));

249 | Serial.print(_axisName);

250 | Serial.println(F(" motor:"));

251 |

252 | //print something to prevent the connection from timing out

253 | Serial.print(F(""));

254 |

255 | int i = 0;

256 | double encoderPos = motorGearboxEncoder.encoder.read(); //record the position now

257 |

258 | //move the motor

259 | while (i < 1000){

260 | motorGearboxEncoder.motor.directWrite(255);

261 | i++;

262 | maslowDelay(1);

263 | if (sys.stop){return;}

264 | }

265 |

266 | //check to see if it moved

267 | if(encoderPos - motorGearboxEncoder.encoder.read() > 500){

268 | Serial.println(F("Direction 1 - Pass"));

269 | }

270 | else{

271 | Serial.println(F("Direction 1 - Fail"));

272 | }

273 |

274 | //record the position again

275 | encoderPos = motorGearboxEncoder.encoder.read();

276 | Serial.print(F(""));

277 |

278 | //move the motor in the other direction

279 | i = 0;

280 | while (i < 1000){

281 | motorGearboxEncoder.motor.directWrite(-255);

282 | i++;

283 | maslowDelay(1);

284 | if (sys.stop){return;}

285 | }

286 |

287 | //check to see if it moved

288 | if(encoderPos - motorGearboxEncoder.encoder.read() < -500){

289 | Serial.println(F("Direction 2 - Pass"));

290 | }

291 | else{

292 | Serial.println(F("Direction 2 - Fail"));

293 | }

294 |

295 | //stop the motor

296 | motorGearboxEncoder.motor.directWrite(0);

297 | Serial.print(F(""));

298 | }

299 |

300 | double Axis::pidInput(){ return _pidInput * *_mmPerRotation;}

301 | double Axis::pidOutput(){ return _pidOutput;}

302 |

--------------------------------------------------------------------------------

/Firmware-1.24/cnc_ctrl_v1/Axis.h:

--------------------------------------------------------------------------------

1 | /*This file is part of the Maslow Control Software.

2 |

3 | The Maslow Control Software is free software: you can redistribute it and/or modify

4 | it under the terms of the GNU General Public License as published by

5 | the Free Software Foundation, either version 3 of the License, or

6 | (at your option) any later version.

7 |

8 | Maslow Control Software is distributed in the hope that it will be useful,

9 | but WITHOUT ANY WARRANTY; without even the implied warranty of

10 | MERCHANTABILITY or FITNESS FOR A PARTICULAR PURPOSE. See the

11 | GNU General Public License for more details.

12 |

13 | You should have received a copy of the GNU General Public License

14 | along with the Maslow Control Software. If not, see .

15 |

16 | Copyright 2014-2017 Bar Smith*/

17 |

18 | #ifndef Axis_h

19 | #define Axis_h

20 |

21 | class Axis{

22 | public:

23 | void setup(const int& pwmPin, const int& directionPin1, const int& directionPin2, const int& encoderPin1, const int& encoderPin2, const char& axisName, const unsigned long& loopInterval);

24 | void write(const float& targetPosition);

25 | float read();

26 | void set(const float& newAxisPosition);

27 | void setSteps(const long& steps);

28 | int updatePositionFromEncoder();

29 | void initializePID(const unsigned long& loopInterval);

30 | int detach();

31 | int attach();

32 | void detachIfIdle();

33 | void endMove(const float& finalTarget);

34 | void stop();

35 | float target();

36 | float error();

37 | float setpoint();

38 | void computePID();

39 | void disablePositionPID();

40 | void enablePositionPID();

41 | void setPIDAggressiveness(float aggressiveness);

42 | void test();

43 | void changePitch(float* newPitch);

44 | float getPitch();

45 | void changeEncoderResolution(float* newResolution);

46 | bool attached();

47 | MotorGearboxEncoder motorGearboxEncoder;

48 | void setPIDValues(float* Kp, float* Ki, float* Kd, float* propWeight, float* KpV, float* KiV, float* KdV, float* propWeightV);

49 | String getPIDString();

50 | double pidInput();

51 | double pidOutput();

52 | long steps();

53 |

54 | private:

55 | int _PWMread(int pin);

56 | void _writeFloat(const unsigned int& addr, const float& x);

57 | float _readFloat(const unsigned int& addr);

58 | unsigned long _timeLastMoved;

59 | volatile double _pidSetpoint;

60 | volatile double _pidInput;

61 | volatile double _pidOutput;

62 | float *_Kp, *_Ki, *_Kd;

63 | PID _pidController;

64 | float *_mmPerRotation;

65 | float *_encoderSteps;

66 | bool _disableAxisForTesting = false;

67 | char _axisName;

68 | };

69 |

70 | #endif

71 |

--------------------------------------------------------------------------------

/Firmware-1.24/cnc_ctrl_v1/Config.h:

--------------------------------------------------------------------------------

1 | /*This file is part of the Maslow Control Software.

2 | The Maslow Control Software is free software: you can redistribute it and/or modify

3 | it under the terms of the GNU General Public License as published by

4 | the Free Software Foundation, either version 3 of the License, or

5 | (at your option) any later version.

6 | Maslow Control Software is distributed in the hope that it will be useful,

7 | but WITHOUT ANY WARRANTY; without even the implied warranty of

8 | MERCHANTABILITY or FITNESS FOR A PARTICULAR PURPOSE. See the

9 | GNU General Public License for more details.

10 | You should have received a copy of the GNU General Public License

11 | along with the Maslow Control Software. If not, see .

12 |

13 | Copyright 2014-2017 Bar Smith*/

14 |

15 | // This file contains precompile configuration settings that apply to the

16 | // whole system

17 |

18 | #ifndef config_h

19 | #define config_h

20 |

21 | // Debugging Options

22 | #define verboseDebug 0 // set to 0 for no debug messages, 1 for single-line messages, 2 to also output ring buffer contents

23 | #define misloopDebug 0 // set to 1 for a warning every time the movement loop fails

24 | // to complete before being interrupted, helpful for loop

25 | // LOOPINTERVAL tuning

26 | #define KINEMATICSDBG 0 // set to 1 for additional kinematics debug messaging

27 |

28 | // #define FAKE_SERVO // Uncomment this line to cause the Firmware to mimic

29 | // a servo updating the encoder steps even if no servo

30 | // is connected. Useful for testing on an arduino only

31 |

32 | // #define SIMAVR // Uncomment this if you plan to run the Firmware in the simavr

33 | // simulator. Normally, you would not define this directly, but

34 | // use PlatformIO to build the simavr environment.

35 |

36 | #define LOOPINTERVAL 10000 // What is the frequency of the PID loop in microseconds

37 |

38 | // Define version detect pins

39 | #define VERS1 22

40 | #define VERS2 23

41 | #define VERS3 24

42 | #define VERS4 25

43 | #define VERS5 26

44 | #define VERS6 27

45 |

46 | // Serial variables

47 | #define INCBUFFERLENGTH 128 // The number of bytes(characters) allocated to the

48 | // incoming buffer.

49 | #define EXPGCODELINE 60 // Maximum expected Gcode line length in characters

50 | // including line ending character(s). Assumes

51 | // client will not send more than this. Ground

52 | // Control is currently set to 60. NIST spec allows

53 | // 256. This value must be <= INCBUFFERLENGTH

54 | #define MAXBUFFERLINES 4 // The maximum number of lines allowed in the buffer

55 | #define POSITIONTIMEOUT 200 // The minimum number of milliseconds between

56 | // position reports sent to Ground Control. This

57 | // cannot be larger than the connection timout in

58 | // Ground Control which is 2000, a smaller number

59 | // takes more processing time for sending data

60 | // a larger number make position updates in GC less

61 | // smooth. This is only a minimum, and the actual

62 | // timeout could be significantly larger.

63 |

64 | #endif

65 |

--------------------------------------------------------------------------------

/Firmware-1.24/cnc_ctrl_v1/Encoder.cpp:

--------------------------------------------------------------------------------

1 |

2 | #include "Maslow.h"

3 |

4 | // Yes, all the code is in the header file, to provide the user

5 | // configure options with #define (before they include it), and

6 | // to facilitate some crafty optimizations!

7 |

8 | Encoder_internal_state_t * Encoder::interruptArgs[];

9 |

10 |

11 |

--------------------------------------------------------------------------------

/Firmware-1.24/cnc_ctrl_v1/GCode.h:

--------------------------------------------------------------------------------

1 | /*This file is part of the Maslow Control Software.

2 |

3 | The Maslow Control Software is free software: you can redistribute it and/or modify

4 | it under the terms of the GNU General Public License as published by

5 | the Free Software Foundation, either version 3 of the License, or

6 | (at your option) any later version.

7 |

8 | Maslow Control Software is distributed in the hope that it will be useful,

9 | but WITHOUT ANY WARRANTY; without even the implied warranty of

10 | MERCHANTABILITY or FITNESS FOR A PARTICULAR PURPOSE. See the

11 | GNU General Public License for more details.

12 |

13 | You should have received a copy of the GNU General Public License

14 | along with the Maslow Control Software. If not, see .

15 |

16 | Copyright 2014-2017 Bar Smith*/

17 |

18 | #ifndef gcode_h

19 | #define gcode_h

20 |

21 | // Define line flags. Includes comment type tracking and line overflow detection.

22 | #define LINE_FLAG_COMMENT_PARENTHESES bit(0)

23 | #define LINE_FLAG_COMMENT_SEMICOLON bit(1)

24 |

25 | extern String readyCommandString; //next command queued up and ready to send

26 | extern String gcodeLine; //The next individual line of gcode (for example G91 G01 X19 would be run as two lines)

27 |

28 | void initGCode();

29 | void gcodeExecuteLoop();

30 | void readSerialCommands();

31 | String gcodeBufferReadline();

32 | int findEndOfNumber(const String&, const int&);

33 | float extractGcodeValue(const String&, char, const float&);

34 | byte executeBcodeLine(const String&);

35 | void executeGcodeLine(const String&);

36 | void executeMcodeLine(const String&);

37 | void executeOtherCodeLine(const String&);

38 | int findNextGM(const String&, const int&);

39 | void sanitizeCommandString(String&);

40 | byte interpretCommandString(String&);

41 | void G1(const String&, int);

42 | void G2(const String&, int);

43 | void G4(const String&);

44 | void G10(const String&);

45 | void G38(const String&);

46 | void setInchesToMillimetersConversion(float);

47 | extern int SpindlePowerControlPin;

48 | extern int ProbePin;

49 |

50 | #endif

51 |

--------------------------------------------------------------------------------

/Firmware-1.24/cnc_ctrl_v1/Kinematics.cpp:

--------------------------------------------------------------------------------

1 | /*This file is part of the Maslow Control Software.

2 |

3 | The Maslow Control Software is free software: you can redistribute it and/or modify

4 | it under the terms of the GNU General Public License as published by

5 | the Free Software Foundation, either version 3 of the License, or

6 | (at your option) any later version.

7 |

8 | Maslow Control Software is distributed in the hope that it will be useful,

9 | but WITHOUT ANY WARRANTY; without even the implied warranty of

10 | MERCHANTABILITY or FITNESS FOR A PARTICULAR PURPOSE. See the

11 | GNU General Public License for more details.

12 |

13 | You should have received a copy of the GNU General Public License

14 | along with the Maslow Control Software. If not, see .

15 |

16 | Copyright 2014-2017 Bar Smith*/

17 |

18 | /*

19 | The Kinematics module relates the lengths of the chains to the position of the cutting head

20 | in X-Y space.

21 | */

22 |

23 | #include "Maslow.h"

24 |

25 |

26 | Kinematics::Kinematics(){

27 | recomputeGeometry();

28 | }

29 |

30 | void Kinematics::init(){

31 | recomputeGeometry();

32 | if (sys.state != STATE_OLD_SETTINGS){

33 | forward(leftAxis.read(), rightAxis.read(), &sys.xPosition, &sys.yPosition, sys.xPosition, sys.yPosition);

34 | }

35 | }

36 |

37 | void Kinematics::_verifyValidTarget(float* xTarget,float* yTarget){

38 | //If the target point is beyond one of the edges of the board, the machine stops at the edge

39 |

40 | *xTarget = (*xTarget < -halfWidth) ? -halfWidth : (*xTarget > halfWidth) ? halfWidth : *xTarget;

41 | *yTarget = (*yTarget < -halfHeight) ? -halfHeight : (*yTarget > halfHeight) ? halfHeight : *yTarget;

42 |

43 | }

44 |

45 | void Kinematics::recomputeGeometry(){

46 | /*

47 | Some variables are computed on class creation for the geometry of the machine to reduce overhead,

48 | calling this function regenerates those values. These are all floats so they take up

49 | ~32bytes of RAM to keep them in memory.

50 | */

51 | Phi = -0.2;

52 | h = sqrt((sysSettings.sledWidth/2)*(sysSettings.sledWidth/2) + sysSettings.sledHeight * sysSettings.sledHeight);

53 | Theta = atan(2*sysSettings.sledHeight/sysSettings.sledWidth);

54 | Psi1 = Theta - Phi;

55 | Psi2 = Theta + Phi;

56 |

57 | halfWidth = sysSettings.machineWidth / 2.0;

58 | halfHeight = sysSettings.machineHeight / 2.0;

59 | _xCordOfMotor = sysSettings.distBetweenMotors/2;

60 | _yCordOfMotor = halfHeight + sysSettings.motorOffsetY;

61 |

62 | }

63 |

64 | void Kinematics::inverse(float xTarget,float yTarget, float* aChainLength, float* bChainLength){

65 | /*

66 |

67 | This function works as a switch to call either the quadrilateralInverse kinematic function

68 | or the triangularInverse kinematic function

69 |

70 | */

71 |

72 | if(sysSettings.kinematicsType == 1){

73 | quadrilateralInverse(xTarget, yTarget, aChainLength, bChainLength);

74 | }

75 | else{

76 | triangularInverse(xTarget, yTarget, aChainLength, bChainLength);

77 | }

78 |

79 | }

80 |

81 | void Kinematics::quadrilateralInverse(float xTarget,float yTarget, float* aChainLength, float* bChainLength){

82 |

83 | //Confirm that the coordinates are on the wood

84 | _verifyValidTarget(&xTarget, &yTarget);

85 |

86 | //coordinate shift to put (0,0) in the center of the plywood from the left sprocket

87 | y = (halfHeight) + sysSettings.motorOffsetY - yTarget;

88 | x = (sysSettings.distBetweenMotors/2.0) + xTarget;

89 |

90 | //Coordinates definition:

91 | // x -->, y |

92 | // v

93 | // (0,0) at center of left sprocket

94 | // upper left corner of plywood (270, 270)

95 |

96 | byte Tries = 0; //initialize

97 | if(x > sysSettings.distBetweenMotors/2.0){ //the right half of the board mirrors the left half so all computations are done using left half coordinates.

98 | x = sysSettings.distBetweenMotors-x; //Chain lengths are swapped at exit if the x,y is on the right half

99 | Mirror = true;

100 | }

101 | else{

102 | Mirror = false;

103 | }

104 |

105 | TanGamma = y/x;

106 | TanLambda = y/(sysSettings.distBetweenMotors-x);

107 | Y1Plus = R * sqrt(1 + TanGamma * TanGamma);

108 | Y2Plus = R * sqrt(1 + TanLambda * TanLambda);

109 |

110 |

111 | while (Tries <= KINEMATICSMAXINVERSE) {

112 |

113 | _MyTrig();

114 | //These criteria will be zero when the correct values are reached

115 | //They are negated here as a numerical efficiency expedient

116 |

117 | Crit[0]= - _moment(Y1Plus, Y2Plus, MySinPhi, SinPsi1, CosPsi1, SinPsi2, CosPsi2);

118 | Crit[1] = - _YOffsetEqn(Y1Plus, x - h * CosPsi1, SinPsi1);

119 | Crit[2] = - _YOffsetEqn(Y2Plus, sysSettings.distBetweenMotors - (x + h * CosPsi2), SinPsi2);

120 |

121 | if (abs(Crit[0]) < KINEMATICSMAXERROR) {

122 | if (abs(Crit[1]) < KINEMATICSMAXERROR) {

123 | if (abs(Crit[2]) < KINEMATICSMAXERROR){

124 | break;

125 | }

126 | }

127 | }

128 |

129 | //estimate the tilt angle that results in zero net _moment about the pen

130 | //and refine the estimate until the error is acceptable or time runs out

131 |

132 | //Estimate the Jacobian components

133 |

134 | Jac[0] = (_moment( Y1Plus, Y2Plus, MySinPhiDelta, SinPsi1D, CosPsi1D, SinPsi2D, CosPsi2D) + Crit[0])/DELTAPHI;

135 | Jac[1] = (_moment( Y1Plus + DELTAY, Y2Plus, MySinPhi, SinPsi1, CosPsi1, SinPsi2, CosPsi2) + Crit[0])/DELTAY;

136 | Jac[2] = (_moment(Y1Plus, Y2Plus + DELTAY, MySinPhi, SinPsi1, CosPsi1, SinPsi2, CosPsi2) + Crit[0])/DELTAY;

137 | Jac[3] = (_YOffsetEqn(Y1Plus, x - h * CosPsi1D, SinPsi1D) + Crit[1])/DELTAPHI;

138 | Jac[4] = (_YOffsetEqn(Y1Plus + DELTAY, x - h * CosPsi1,SinPsi1) + Crit[1])/DELTAY;

139 | Jac[5] = 0.0;

140 | Jac[6] = (_YOffsetEqn(Y2Plus, sysSettings.distBetweenMotors - (x + h * CosPsi2D), SinPsi2D) + Crit[2])/DELTAPHI;

141 | Jac[7] = 0.0;

142 | Jac[8] = (_YOffsetEqn(Y2Plus + DELTAY, sysSettings.distBetweenMotors - (x + h * CosPsi2D), SinPsi2) + Crit[2])/DELTAY;

143 |

144 |

145 | //solve for the next guess

146 | _MatSolv(); // solves the matrix equation Jx=-Criterion

147 |

148 | // update the variables with the new estimate

149 |

150 | Phi = Phi + Solution[0];

151 | Y1Plus = Y1Plus + Solution[1]; //don't allow the anchor points to be inside a sprocket

152 | Y1Plus = (Y1Plus < R) ? R : Y1Plus;

153 |

154 | Y2Plus = Y2Plus + Solution[2]; //don't allow the anchor points to be inside a sprocke

155 | Y2Plus = (Y2Plus < R) ? R : Y2Plus;

156 |

157 | Psi1 = Theta - Phi;

158 | Psi2 = Theta + Phi;

159 |

160 | Tries++; // increment itteration count

161 |

162 | }

163 |

164 | //Variables are within accuracy limits

165 | // perform output computation

166 |

167 | Offsetx1 = h * CosPsi1;

168 | Offsetx2 = h * CosPsi2;

169 | Offsety1 = h * SinPsi1;

170 | Offsety2 = h * SinPsi2;

171 | TanGamma = (y - Offsety1 + Y1Plus)/(x - Offsetx1);

172 | TanLambda = (y - Offsety2 + Y2Plus)/(sysSettings.distBetweenMotors -(x + Offsetx2));

173 | Gamma = atan(TanGamma);

174 | Lambda =atan(TanLambda);

175 |

176 | //compute the chain lengths

177 |

178 | if(Mirror){

179 | Chain2 = sqrt((x - Offsetx1)*(x - Offsetx1) + (y + Y1Plus - Offsety1)*(y + Y1Plus - Offsety1)) - R * TanGamma + R * Gamma; //right chain length

180 | Chain1 = sqrt((sysSettings.distBetweenMotors - (x + Offsetx2))*(sysSettings.distBetweenMotors - (x + Offsetx2))+(y + Y2Plus - Offsety2)*(y + Y2Plus - Offsety2)) - R * TanLambda + R * Lambda; //left chain length

181 | }

182 | else{

183 | Chain1 = sqrt((x - Offsetx1)*(x - Offsetx1) + (y + Y1Plus - Offsety1)*(y + Y1Plus - Offsety1)) - R * TanGamma + R * Gamma; //left chain length

184 | Chain2 = sqrt((sysSettings.distBetweenMotors - (x + Offsetx2))*(sysSettings.distBetweenMotors - (x + Offsetx2))+(y + Y2Plus - Offsety2)*(y + Y2Plus - Offsety2)) - R * TanLambda + R * Lambda; //right chain length

185 | }

186 |

187 | *aChainLength = Chain1;

188 | *bChainLength = Chain2;

189 |

190 | }

191 |

192 | void Kinematics::triangularInverse(float xTarget,float yTarget, float* aChainLength, float* bChainLength){

193 | /*

194 |

195 | The inverse kinematics (relating an xy coordinate pair to the required chain lengths to hit that point)

196 | function for a triangular set up where the chains meet at a point, or are arranged so that they simulate

197 | meeting at a point.

198 |

199 | */

200 |

201 | //Confirm that the coordinates are on the wood

202 | _verifyValidTarget(&xTarget, &yTarget);

203 |

204 | //Set up variables

205 | float Chain1Angle = 0;

206 | float Chain2Angle = 0;

207 | float Chain1AroundSprocket = 0;

208 | float Chain2AroundSprocket = 0;

209 |

210 | //Calculate motor axes length to the bit

211 | float Motor1Distance = sqrt(pow((-1*_xCordOfMotor - xTarget),2)+pow((_yCordOfMotor - yTarget),2));

212 | float Motor2Distance = sqrt(pow((_xCordOfMotor - xTarget),2)+pow((_yCordOfMotor - yTarget),2));

213 |

214 | //Calculate the chain angles from horizontal, based on if the chain connects to the sled from the top or bottom of the sprocket

215 | if(sysSettings.chainOverSprocket == 1){

216 | Chain1Angle = asin((_yCordOfMotor - yTarget)/Motor1Distance) + asin(R/Motor1Distance);

217 | Chain2Angle = asin((_yCordOfMotor - yTarget)/Motor2Distance) + asin(R/Motor2Distance);

218 |

219 | Chain1AroundSprocket = R * Chain1Angle;

220 | Chain2AroundSprocket = R * Chain2Angle;

221 | }

222 | else{

223 | Chain1Angle = asin((_yCordOfMotor - yTarget)/Motor1Distance) - asin(R/Motor1Distance);

224 | Chain2Angle = asin((_yCordOfMotor - yTarget)/Motor2Distance) - asin(R/Motor2Distance);

225 |

226 | Chain1AroundSprocket = R * (3.14159 - Chain1Angle);

227 | Chain2AroundSprocket = R * (3.14159 - Chain2Angle);

228 | }

229 |

230 | //Calculate the straight chain length from the sprocket to the bit

231 | float Chain1Straight = sqrt(pow(Motor1Distance,2)-pow(R,2));

232 | float Chain2Straight = sqrt(pow(Motor2Distance,2)-pow(R,2));

233 |

234 | //Correct the straight chain lengths to account for chain sag

235 | Chain1Straight *= (1 + ((sysSettings.chainSagCorrection / 1000000000000) * pow(cos(Chain1Angle),2) * pow(Chain1Straight,2) * pow((tan(Chain2Angle) * cos(Chain1Angle)) + sin(Chain1Angle),2)));

236 | Chain2Straight *= (1 + ((sysSettings.chainSagCorrection / 1000000000000) * pow(cos(Chain2Angle),2) * pow(Chain2Straight,2) * pow((tan(Chain1Angle) * cos(Chain2Angle)) + sin(Chain2Angle),2)));

237 |

238 | //Calculate total chain lengths accounting for sprocket geometry and chain sag

239 | float Chain1 = Chain1AroundSprocket + Chain1Straight * (1.0f + sysSettings.leftChainTolerance / 100.0f);

240 | float Chain2 = Chain2AroundSprocket + Chain2Straight * (1.0f + sysSettings.rightChainTolerance / 100.0f);

241 |

242 | //Subtract of the virtual length which is added to the chain by the rotation mechanism

243 | Chain1 = Chain1 - sysSettings.rotationDiskRadius;

244 | Chain2 = Chain2 - sysSettings.rotationDiskRadius;

245 |

246 | *aChainLength = Chain1;

247 | *bChainLength = Chain2;

248 | }

249 |

250 | void Kinematics::forward(const float& chainALength, const float& chainBLength, float* xPos, float* yPos, float xGuess, float yGuess){

251 |

252 | Serial.println(F("[Forward Calculating Position]"));

253 |

254 |

255 | float guessLengthA;

256 | float guessLengthB;

257 |

258 | int guessCount = 0;

259 |

260 | while(1){

261 |

262 |

263 | //check our guess

264 | inverse(xGuess, yGuess, &guessLengthA, &guessLengthB);

265 |

266 | float aChainError = chainALength - guessLengthA;

267 | float bChainError = chainBLength - guessLengthB;

268 |

269 |

270 | //adjust the guess based on the result

271 | xGuess = xGuess + .1*aChainError - .1*bChainError;

272 | yGuess = yGuess - .1*aChainError - .1*bChainError;

273 |

274 | guessCount++;

275 |

276 | #if defined (KINEMATICSDBG) && KINEMATICSDBG > 0

277 | Serial.print(F("[PEk:"));

278 | Serial.print(aChainError);

279 | Serial.print(',');

280 | Serial.print(bChainError);

281 | Serial.print(',');

282 | Serial.print('0');

283 | Serial.println(F("]"));

284 | #endif

285 |

286 | execSystemRealtime();

287 | // No need for sys.stop check here

288 |

289 | //if we've converged on the point...or it's time to give up, exit the loop

290 | if((abs(aChainError) < .1 && abs(bChainError) < .1) or guessCount > KINEMATICSMAXGUESS or guessLengthA > sysSettings.chainLength or guessLengthB > sysSettings.chainLength){

291 | if((guessCount > KINEMATICSMAXGUESS) or guessLengthA > sysSettings.chainLength or guessLengthB > sysSettings.chainLength){

292 | Serial.print(F("Message: Unable to find valid machine position for chain lengths "));

293 | Serial.print(chainALength);

294 | Serial.print(", ");

295 | Serial.print(chainBLength);

296 | Serial.println(F(" . Please set the chains to a known length (Actions -> Set Chain Lengths)"));

297 | *xPos = 0;

298 | *yPos = 0;

299 | }

300 | else{

301 | Serial.println("position loaded at:");

302 | Serial.println(xGuess);

303 | Serial.println(yGuess);

304 | *xPos = xGuess;

305 | *yPos = yGuess;

306 | }

307 | break;

308 | }

309 | }

310 | }

311 |

312 | void Kinematics::_MatSolv(){

313 | float Sum;

314 | int NN;

315 | int i;

316 | int ii;

317 | int J;

318 | int JJ;

319 | int K;

320 | int KK;

321 | int L;

322 | int M;

323 | int N;

324 |

325 | float fact;

326 |

327 | // gaus elimination, no pivot

328 |

329 | N = 3;

330 | NN = N-1;

331 | for (i=1;i<=NN;i++){

332 | J = (N+1-i);

333 | JJ = (J-1) * N-1;

334 | L = J-1;

335 | KK = -1;

336 | for (K=0;K.

15 |

16 | Copyright 2014-2017 Bar Smith*/

17 |

18 | #ifndef Kinematics_h

19 | #define Kinematics_h

20 |

21 |

22 | //Calculation tolerances

23 | #define DELTAPHI 0.001

24 | #define DELTAY 0.01

25 | #define KINEMATICSMAXERROR 0.001

26 | #define KINEMATICSMAXINVERSE 10

27 | #define KINEMATICSMAXGUESS 200

28 |

29 | class Kinematics{

30 | public:

31 | Kinematics();

32 | void init ();

33 | void inverse (float xTarget,float yTarget, float* aChainLength, float* bChainLength);

34 | void quadrilateralInverse (float xTarget,float yTarget, float* aChainLength, float* bChainLength);

35 | void triangularInverse (float xTarget,float yTarget, float* aChainLength, float* bChainLength);

36 | void recomputeGeometry();

37 | void forward(const float& chainALength, const float& chainBLength, float* xPos, float* yPos, float xGuess, float yGuess);

38 | //geometry

39 | float h; //distance between sled attach point and bit

40 | float R = 10.1; //sprocket radius

41 |

42 | float halfWidth; //Half the machine width

43 | float halfHeight; //Half the machine height

44 | private:

45 | float _moment(const float& Y1Plus, const float& Y2Plus, const float& MSinPhi, const float& MSinPsi1, const float& MCosPsi1, const float& MSinPsi2, const float& MCosPsi2);

46 | float _YOffsetEqn(const float& YPlus, const float& Denominator, const float& Psi);

47 | void _MatSolv();

48 | void _MyTrig();

49 | void _verifyValidTarget(float* xTarget,float* yTarget);

50 | //target router bit coordinates.

51 | float x = 0;

52 | float y = 0;

53 | float _xCordOfMotor;

54 | float _yCordOfMotor;

55 |

56 | //utility variables

57 | boolean Mirror;

58 |

59 | //Criterion Computation Variables

60 | float Phi = -0.2;

61 | float TanGamma;

62 | float TanLambda;

63 | float Y1Plus ;

64 | float Y2Plus;

65 | float Theta;

66 | float Psi1 = Theta - Phi;

67 | float Psi2 = Theta + Phi;

68 | float Jac[9];

69 | float Solution[3];

70 | float Crit[3];

71 | float Offsetx1;

72 | float Offsetx2;

73 | float Offsety1;

74 | float Offsety2;

75 | float SinPsi1;

76 | float CosPsi1;

77 | float SinPsi2;

78 | float CosPsi2;

79 | float SinPsi1D;

80 | float CosPsi1D;

81 | float SinPsi2D;

82 | float CosPsi2D;

83 | float MySinPhi;

84 | float MySinPhiDelta;

85 |

86 | //intermediate output

87 | float Lambda;

88 | float Gamma;

89 |

90 | // Motor axes length to the bit for triangular kinematics

91 | float Motor1Distance; //left motor axis distance to sled

92 | float Motor2Distance; //right motor axis distance to sled

93 |

94 | // output = chain lengths measured from 12 o'clock

95 | float Chain1; //left chain length

96 | float Chain2; //right chain length

97 | };

98 |

99 | #endif

100 |

--------------------------------------------------------------------------------

/Firmware-1.24/cnc_ctrl_v1/Maslow.h:

--------------------------------------------------------------------------------

1 | /*This file is part of the Maslow Control Software.

2 | The Maslow Control Software is free software: you can redistribute it and/or modify

3 | it under the terms of the GNU General Public License as published by

4 | the Free Software Foundation, either version 3 of the License, or

5 | (at your option) any later version.

6 | Maslow Control Software is distributed in the hope that it will be useful,

7 | but WITHOUT ANY WARRANTY; without even the implied warranty of

8 | MERCHANTABILITY or FITNESS FOR A PARTICULAR PURPOSE. See the

9 | GNU General Public License for more details.

10 | You should have received a copy of the GNU General Public License

11 | along with the Maslow Control Software. If not, see .

12 |

13 | Copyright 2014-2017 Bar Smith*/

14 |

15 | // This is the main maslow include file

16 |

17 | #ifndef maslow_h

18 | #define maslow_h

19 |

20 | // Maslow Firmware Version tracking

21 | #define VERSIONNUMBER 1.24

22 |

23 | // Define standard libraries used by maslow.

24 | #include

25 | #include

26 | #include

27 | #include

28 |

29 | // Define the maslow system include files. This ensures that dependencies are

30 | // loaded in the proper order. Be careful moving these around.

31 | #include "Config.h"

32 | #include "TimerOne.h"

33 | #include "Motor.h"

34 | #include "PID_v1.h"

35 | #include "utility/direct_pin_read.h"

36 | #include "Encoder.h"

37 | #include "MotorGearboxEncoder.h"

38 | #include "Axis.h"

39 | #include "Kinematics.h"

40 | #include "RingBuffer.h"

41 | #include "GCode.h"

42 | #include "Testing.h"

43 | #include "Motion.h"

44 | #include "Report.h"

45 | #include "Spindle.h"

46 | #include "Probe.h"

47 | #include "Settings.h"

48 | #include "NutsAndBolts.h"

49 | #include "System.h"

50 | #include "SimavrSerial.h"

51 |

52 | #endif

53 |

--------------------------------------------------------------------------------

/Firmware-1.24/cnc_ctrl_v1/Motion.cpp:

--------------------------------------------------------------------------------

1 | /*This file is part of the Maslow Control Software.

2 | The Maslow Control Software is free software: you can redistribute it and/or modify

3 | it under the terms of the GNU General Public License as published by

4 | the Free Software Foundation, either version 3 of the License, or

5 | (at your option) any later version.

6 | Maslow Control Software is distributed in the hope that it will be useful,

7 | but WITHOUT ANY WARRANTY; without even the implied warranty of

8 | MERCHANTABILITY or FITNESS FOR A PARTICULAR PURPOSE. See the

9 | GNU General Public License for more details.

10 | You should have received a copy of the GNU General Public License

11 | along with the Maslow Control Software. If not, see .

12 |

13 | Copyright 2014-2017 Bar Smith*/

14 |

15 | // This contains all of the Motion commands

16 |

17 | #include "Maslow.h"

18 |

19 | // Flag for when to send movement commands

20 | volatile bool movementUpdated = false;

21 | // Global variables for misloop tracking

22 | #if misloopDebug > 0

23 | volatile bool inMovementLoop = false;

24 | volatile bool movementFail = false;

25 | #endif

26 |

27 | void initMotion(){

28 | // Called on startup or after a stop command

29 | leftAxis.stop();

30 | rightAxis.stop();

31 | if(sysSettings.zAxisAttached){

32 | zAxis.stop();

33 | }

34 | }

35 |

36 |

37 | float calculateFeedrate(const float& stepSizeMM, const float& usPerStep){

38 | /*

39 | Calculate the time delay between each step for a given feedrate

40 | */

41 |

42 | #define MINUTEINUS 60000000.0

43 |

44 | // derivation: ms / step = 1 min in ms / dist in one min

45 |

46 | float tempFeedrate = (stepSizeMM*MINUTEINUS)/usPerStep;

47 |

48 | return tempFeedrate;

49 | }

50 |

51 | float computeStepSize(const float& MMPerMin){

52 | /*

53 |

54 | Determines the minimum step size which can be taken for the given feed-rate

55 | based on the loop interval frequency. Converts to MM per microsecond first,

56 | then mutiplies by the number of microseconds in each loop interval

57 |

58 | */

59 | return LOOPINTERVAL*(MMPerMin/(60 * 1000000));

60 | }

61 |

62 | void movementUpdate(){

63 | #if misloopDebug > 0

64 | if (movementFail){

65 | Serial.println("Movement loop failed to complete before interrupt.");

66 | movementFail = false;

67 | }

68 | #endif

69 | movementUpdated = true;

70 | }

71 |

72 |

73 | // why does this return anything

74 | int coordinatedMove(const float& xEnd, const float& yEnd, const float& zEnd, float MMPerMin){

75 |

76 | /*The move() function moves the tool in a straight line to the position (xEnd, yEnd) at

77 | the speed moveSpeed. Movements are correlated so that regardless of the distances moved in each

78 | direction, the tool moves to the target in a straight line. This function is used by the G00

79 | and G01 commands. The units at this point should all be in mm or mm per minute*/

80 |

81 | float xStartingLocation = sys.xPosition;

82 | float yStartingLocation = sys.yPosition;

83 | float zStartingLocation = zAxis.read(); // I don't know why we treat the zaxis differently

84 | float zMaxFeed = sysSettings.maxZRPM * abs(zAxis.getPitch());

85 |

86 | //find the total distances to move

87 | float distanceToMoveInMM = sqrt( sq(xEnd - xStartingLocation) + sq(yEnd - yStartingLocation) + sq(zEnd - zStartingLocation));

88 | float xDistanceToMoveInMM = xEnd - xStartingLocation;

89 | float yDistanceToMoveInMM = yEnd - yStartingLocation;

90 | float zDistanceToMoveInMM = zEnd - zStartingLocation;

91 |

92 | //compute feed details

93 | MMPerMin = constrain(MMPerMin, 1, sysSettings.maxFeed); //constrain the maximum feedrate, 35ipm = 900 mmpm

94 | float stepSizeMM = computeStepSize(MMPerMin);

95 | float finalNumberOfSteps = abs(distanceToMoveInMM/stepSizeMM);

96 | float delayTime = LOOPINTERVAL;

97 | float zFeedrate = calculateFeedrate(fabs(zDistanceToMoveInMM/finalNumberOfSteps), delayTime);

98 |

99 | //throttle back federate if it exceeds zaxis max

100 | if (zFeedrate > zMaxFeed){

101 | float zStepSizeMM = computeStepSize(zMaxFeed);

102 | finalNumberOfSteps = abs(zDistanceToMoveInMM/zStepSizeMM);

103 | stepSizeMM = (distanceToMoveInMM/finalNumberOfSteps);

104 | MMPerMin = calculateFeedrate(stepSizeMM, delayTime);

105 | }

106 |

107 | // (fraction of distance in x direction)* size of step toward target

108 | float xStepSize = (xDistanceToMoveInMM/finalNumberOfSteps);

109 | float yStepSize = (yDistanceToMoveInMM/finalNumberOfSteps);

110 | float zStepSize = (zDistanceToMoveInMM/finalNumberOfSteps);

111 |

112 | //attach the axes

113 | leftAxis.attach();

114 | rightAxis.attach();

115 | if(sysSettings.zAxisAttached){

116 | zAxis.attach();

117 | }

118 |

119 | float aChainLength;

120 | float bChainLength;

121 | float zPosition = zStartingLocation;

122 | long numberOfStepsTaken = 0;

123 |

124 | while(numberOfStepsTaken < finalNumberOfSteps){

125 |

126 | #if misloopDebug > 0

127 | inMovementLoop = true;

128 | #endif

129 | //if last movment was performed start the next

130 | if (!movementUpdated) {

131 | //find the target point for this step

132 | // This section ~20us

133 | sys.xPosition += xStepSize;

134 | sys.yPosition += yStepSize;

135 | zPosition += zStepSize;

136 |

137 | //find the chain lengths for this step

138 | // This section ~180us

139 | kinematics.inverse(sys.xPosition,sys.yPosition,&aChainLength,&bChainLength);

140 |

141 | //write to each axis

142 | // This section ~180us

143 | leftAxis.write(aChainLength);

144 | rightAxis.write(bChainLength);

145 | if(sysSettings.zAxisAttached){

146 | zAxis.write(zPosition);

147 | }

148 |

149 | movementUpdate();

150 |

151 | //increment the number of steps taken

152 | numberOfStepsTaken++;

153 |

154 | // Run realtime commands

155 | execSystemRealtime();

156 | if (sys.stop){return 1;}

157 | }

158 | }

159 | #if misloopDebug > 0

160 | inMovementLoop = false;

161 | #endif

162 |

163 | kinematics.inverse(xEnd,yEnd,&aChainLength,&bChainLength);

164 | leftAxis.endMove(aChainLength);

165 | rightAxis.endMove(bChainLength);

166 | if(sysSettings.zAxisAttached){

167 | zAxis.endMove(zPosition);

168 | }

169 |

170 | sys.xPosition = xEnd;

171 | sys.yPosition = yEnd;

172 |

173 | return 1;

174 |

175 | }

176 |

177 | void singleAxisMove(Axis* axis, const float& endPos, const float& MMPerMin){

178 | /*

179 | Takes a pointer to an axis object and moves that axis to endPos at speed MMPerMin

180 | */

181 |

182 | float startingPos = axis->read();

183 | float moveDist = endPos - startingPos; //total distance to move

184 |

185 | float direction = moveDist/abs(moveDist); //determine the direction of the move

186 |

187 | float stepSizeMM = computeStepSize(MMPerMin); //step size in mm

188 |

189 | //the argument to abs should only be a variable -- splitting calc into 2 lines

190 | long finalNumberOfSteps = abs(moveDist/stepSizeMM); //number of steps taken in move

191 | finalNumberOfSteps = abs(finalNumberOfSteps);

192 | stepSizeMM = stepSizeMM*direction;

193 |

194 | long numberOfStepsTaken = 0;

195 |

196 | //attach the axis we want to move

197 | axis->attach();

198 |

199 | float whereAxisShouldBeAtThisStep = startingPos;

200 | #if misloopDebug > 0

201 | inMovementLoop = true;

202 | #endif

203 | while(numberOfStepsTaken < finalNumberOfSteps){

204 | if (!movementUpdated) {

205 | //find the target point for this step

206 | whereAxisShouldBeAtThisStep += stepSizeMM;

207 |

208 | //write to axis

209 | axis->write(whereAxisShouldBeAtThisStep);

210 | movementUpdate();

211 |

212 | // Run realtime commands

213 | execSystemRealtime();

214 | if (sys.stop){return;}

215 |

216 | //increment the number of steps taken

217 | numberOfStepsTaken++;

218 | }

219 | }

220 | #if misloopDebug > 0

221 | inMovementLoop = false;

222 | #endif

223 |

224 | axis->endMove(endPos);

225 |

226 | }

227 |

228 | // return the sign of the parameter

229 | int sign(double x) { return x<0 ? -1 : 1; }

230 |

231 | // why does this return anything

232 | int arc(const float& X1, const float& Y1, const float& Z1, const float& X2, const float& Y2, const float& Z2, const float& centerX, const float& centerY, const float& MMPerMin, const float& direction){

233 | /*

234 |

235 | Move the machine through an arc from point (X1, Y1) to point (X2, Y2) along the

236 | arc defined by center (centerX, centerY) at speed MMPerMin

237 |

238 | */

239 |

240 | //compute geometry

241 | float pi = 3.1415;

242 | float radius = sqrt( sq(centerX - X1) + sq(centerY - Y1) );

243 | float circumference = 2.0*pi*radius;

244 |

245 | float startingAngle = atan2(Y1 - centerY, X1 - centerX);

246 | float endingAngle = atan2(Y2 - centerY, X2 - centerX);

247 |

248 | // compute chord height of arc

249 | float chordSquared = sqrt(sq(X2 - X1) + sq(Y2 - Y1));

250 | float tau = sqrt( sq(radius) - (chordSquared/4.0));

251 | float chordHeight = radius - tau;

252 |

253 | //compute angle between lines

254 | float theta = endingAngle - startingAngle;

255 | if (direction == COUNTERCLOCKWISE){

256 | if (theta <= 0){

257 | theta += 2*pi;

258 | }

259 | }

260 | else {

261 | //CLOCKWISE

262 | if (theta >= 0){

263 | theta -= 2*pi;

264 | }

265 | }

266 | if ((sign(theta) != sign(direction)) || ((abs(chordHeight) < .01) && (abs(theta) < 0.5)) || (radius > 25400)) {

267 | // There is a parameter error in this line of gcode, either in the size of the angle calculated

268 | // or the chord height of the arc between the starting and ending points

269 | // In either case, the gcode cut was essentially a straight line, so

270 | // Replace it with a G1 cut to the endpoint

271 | String gcodeSubstitution = "G1 X";

272 | gcodeSubstitution = gcodeSubstitution + String(X2 / sys.inchesToMMConversion, 3) + " Y" + String(Y2 / sys.inchesToMMConversion, 3) + " Z" + String(Z2 / sys.inchesToMMConversion, 3) + " ";

273 | Serial.println("Large-radius arc replaced by straight line to improve accuracy: " + gcodeSubstitution);