├── .gitattributes

├── CHANGELOG.md

├── LICENSE

├── README.md

├── THIRDPARTY

├── cfdtool.m

├── download.png

├── screenshot.jpg

└── tutorials

├── 01_Quickstart

├── 02_heat_exchanger1.fes

├── 03_axisymmetric_flow1.fes

├── 04_natural_convection1.fes

├── axisymmetric_flow1.jpg

├── heat_exchanger1.jpg

└── natural_convection1.jpg

├── 02_Heat_Transfer

├── 01_heat_transfer1.fes

├── 02_heat_transfer2.fes

├── 03_heat_transfer3.fes

├── 05_thermal_bridge1.fes

├── 07_heat_transfer5.fes

├── heat_transfer1.jpg

├── heat_transfer2.jpg

├── heat_transfer3.jpg

├── heat_transfer5.jpg

└── thermal_bridge1.jpg

├── 03_Fluid_Dynamics

├── 01_channel_flow1.fes

├── 02_driven_cavity1.fes

├── 03_flow_around_cylinder1.fes

├── 04_backwards_facing_step1.fes

├── 05_vortex_flow1.fes

├── 07_compressible_euler1.fes

├── 08_compressible_euler2.fes

├── 09_turbulent_channel1.fes

├── 10_turbulent_flow1.fes

├── 11_taylor_couette1.fes

├── 12_non_newtonian1.fes

├── 13_compressible_flow1.fes

├── backwards_facing_step1.jpg

├── channel_flow1.jpg

├── compressible_euler1.jpg

├── compressible_euler2.jpg

├── compressible_flow1.jpg

├── driven_cavity1.jpg

├── flow_around_cylinder1.jpg

├── non_newtonian1.jpg

├── taylor_couette1.jpg

├── turbulent_channel1.jpg

├── turbulent_flow1.jpg

└── vortex_flow1.jpg

└── webtutlist

/.gitattributes:

--------------------------------------------------------------------------------

1 | *.html linguist-detectable=false

2 | *.js linguist-detectable=false

3 | *.md linguist-detectable=false

4 | *.xml linguist-detectable=false

--------------------------------------------------------------------------------

/CHANGELOG.md:

--------------------------------------------------------------------------------

1 | CFDTool Changelog

2 | ===================

3 |

4 |

5 | 2025-02-14 version 1.10.3

6 | -------------------------

7 |

8 | - Warning for MATLAB 2025a GUI incompatibility and performance

9 | - Add checkbox toggle for flow mode automatic pressure contstraint

10 | - Warning for incompatible (openfoam.org foundation) OpenFOAM installation

11 | - Minor bug fixes

12 |

13 | 2024-11-27 version 1.10.2

14 | -------------------------

15 |

16 | - OpenFOAM/SU2 add option to save casefiles on error

17 | - GUI consistency improvements

18 | - SU2 default to V2003m SST turbulence model

19 | - Minor bug fixes

20 |

21 |

22 | 2024-10-20 version 1.10.1

23 | -------------------------

24 |

25 | - Added categories to physics mode selection list

26 | - Recommendation to use ESI openfoam.com (not openfoam.org)

27 | - Minor bug fixes

28 |

29 |

30 | 2024-09-30 version 1.10

31 | -----------------------

32 |

33 | - Unified UI with FEATool

34 | - Physics mode for compressible high Ma number turbulent flows

35 | + Add tutorial model for supersonic compressible flow past a prism

36 | - Updated OpenFOAM solver interface

37 | + Support coupled flow + heat transfer

38 | + Support for multiple subdomains

39 | + Support for chtMultiRegionFoam, buoyantBoussinesqFoam, and sonicFoam solvers

40 | + CFD script model support for the OpenFOAM solver

41 | - SU2 support for turbulent compressible and high Ma flows

42 | - Improved UI performance and responsiveness

43 |

44 |

45 | 2024-06-25 version 1.9.6

46 | ------------------------

47 |

48 | - MacOS App OpenFOAM support (https://github.com/gerlero/openfoam-app)

49 | - Removed averaging of initial conditions for boundaries shared between subdomains

50 | - Improved performance of Robin boundary condition assembly

51 | - Fix for 3D geometry plotting (identification and deduplication of shared boundaries)

52 |

53 |

54 | 2024-03-15 version 1.9.5

55 | ------------------------

56 |

57 | - Support CSG formulas for robust (STL/OBJ) meshes

58 | - New supersonic flow passed a wedge tutorial

59 | - Change supersonic flow over bump tutorial to 3D

60 | - Support HOME/Documents/MATLAB/.cfdtool/cfdtool.ini configuration

61 | + performance mex and mumps solver disabled by default

62 | - Fix bug in geometry object rotation

63 | - Minor fixes

64 |

65 |

66 | 2023-11-30 version 1.9.4

67 | ------------------------

68 |

69 | - Fix Excel (xlsx) data export

70 | - Add Data Export dialog box

71 | + Support custom data export expressions

72 | + Support custom data export coordinates

73 | - Improved app startup and shutdown time

74 |

75 |

76 | 2023-09-10 version 1.9.3

77 | ------------------------

78 |

79 | - Add equation mode menu option to remove physics modes

80 | - Updated OpenCASCADE geometry kernel to v7.7.2

81 | - Fix 2D STEP/IGES geometry import

82 | - Fix plot 3D block/hexahedal grid

83 | - Fix for Matlab 2023b

84 |

85 |

86 | 2023-03-12 version 1.9.2

87 | ------------------------

88 |

89 | - Show axes coordinate system orientation for 3D views

90 | - Update MUMPS linear solver

91 | + Support all MATLAB versions (Windows and Linux)

92 | + Support for Intel MKL BLAS, OpenMP, and >2GB large arrays

93 | - Updated SU2 Code CFD solver to v7.5.0

94 | - Add functionality to show geometry object information

95 |

96 |

97 | 2022-10-20 version 1.9.1

98 | ------------------------

99 |

100 | - Updated m-file export output to support the MATLAB "publish" command

101 | - New "Create Model Report" menu option to Generate model reports in

102 | Html, PDF, Microsoft Word/PDF, Latex, and XML formats

103 | - Updated OpenCASCADE geometry kernel to v7.6.3

104 | - Updated SU2 Code CFD solver to v7.4.0

105 |

106 |

107 | 2022-08-29 version 1.9

108 | -----------------------

109 |

110 | - Performance improvements for built-in multiphysics solver

111 | - Improved 3D geometry rendering performance

112 | - New 3D geometry defeaturing functionality

113 | - Support for edge/vertex selection for chamfer/fillet operations

114 | - Support for PDF image and Excel data export

115 | - Improved save/load model file performance

116 |

117 |

118 | 2022-06-06 version 1.8.5

119 | ------------------------

120 |

121 | - Fix for STEP geometry import with >= 2 objects

122 | - Improved and faster expression evaluation in assembly

123 |

124 |

125 | 2022-05-09 version 1.8.4

126 | -------------------------

127 |

128 | - Added 2D geometry tool for Bezier and spline curves

129 | - Updated OpenCASCADE geometry kernel to v7.6.2

130 | - Support for binary brep (.bin) geometry format

131 | - Updated SU2 Code CFD solver to v7.3.1

132 | - Added k-Omega wall function support for SU2 solver

133 |

134 |

135 | 2021-12-01 version 1.8.1

136 | -------------------------

137 | - Geometry import option from bitmap image (bmp, jpeg, png)

138 | - Support for structured meshing of geometry primitives

139 | - Updated plotly library to version 2.6.2

140 | - Updated ParaView Glance library to version 4.17.1,

141 | and added support for slice and isosurface plot options

142 | - Linux support for HiDPI screens

143 | - Mouse controls for 3D zoom, pan, and rotate

144 |

145 |

146 | 2021-11-01 version 1.8

147 | ----------------------

148 |

149 | - Improved graphics performance for 3D plots

150 | - Changed 3D plots to fill the whole viewport with

151 | CAD style orbit, pan, and zoom controls

152 | - Added flip/reverse view option by double clicking

153 | on the 3D xy, xz, and yz quickview buttons

154 |

155 |

156 | 2021-08-30 version 1.7.3

157 | ------------------------

158 |

159 | - Added view boundaries/subdomains menu option

160 | (for specifying mesh sizes on individual geometric entities)

161 | - Various performance improvements

162 |

163 |

164 | 2021-05-24 version 1.7.1

165 | ------------------------

166 |

167 | - Preliminary support for built-in and robust 3D mesh generators

168 | - GUI menu option to manually renumber/reassign 3D boundaries

169 | - Heated pipe with cooling fins validation tutorial

170 |

171 |

172 | 2020-04-19 version 1.7

173 | ----------------------

174 |

175 | - Minor update to sync with FEATool v1.14

176 |

177 |

178 | 2020-03-26 version 1.6

179 | ----------------------

180 |

181 | - Updated OpenFOAM and SU2 interfaces to support parallel computations

182 | - Added OpenFOAM binary GUI option to support user defined FOAM solvers

183 | - Added support for ESI-OpenCFD native Windows OpenFOAM distribution

184 |

185 |

186 | 2020-11-01 version 1.5

187 | ----------------------

188 |

189 | - Support 3D geometry and CAD modeling

190 | - SU2 external CFD solver integration

191 |

192 |

193 | 2019-09-01 version 1.4

194 | ----------------------

195 |

196 | - Support for .fes script file format

197 | - Added built in CFD tutorials

198 |

199 |

200 | 2018-11-20 version 1.3

201 | ----------------------

202 |

203 | - Support for supersonic and inviscid compressible flows

204 | (compressible Euler equations)

205 | - OpenFOAM support for inviscid compressible flows

206 | - Monitoring of OpenFOAM convergence curves

207 | - NACA 4-series pre-defined wing geometry object

208 |

209 |

210 | 2018-10-22 version 1.2

211 | ----------------------

212 |

213 | - OpenFOAM external CFD solver integration

214 | - Support for k-epsilon/omega turbulence models (with OpenFOAM)

215 | - Potential flow velocity field initialization

216 | - Improved resolution of curved geometry boundaries

217 |

218 |

219 | 2018-09-24 version 1.1

220 | ----------------------

221 |

222 | - Support for 2D Axisymmetry/Cylindrical coordinates

223 | and flows with swirl (non-zero azimuthal velocity)

224 | - Support for heat transfer modeling in 1D

225 | - Support for importing 2D planar STL CAD geometry files

226 | - Built-in interface to the external mesh generator

227 | Gridgen2D with support for meshing boundary layers

228 | - Support for importing Gmsh, GiD, Triangle, and FEniCS

229 | grid and mesh formats

230 | - Improved parametrization and meshing of curved boundaries

231 | - Added automatic shock capturing and stabilization for

232 | convection dominated flow regimes

233 | - Improved and more efficient flow discretization

234 | - Added advanced postprocessing functionality such as boundary

235 | integration for computation of drag and lift coefficients

236 | - Extended backwards compatibility to MATLAB 2009b

237 |

238 |

239 | 2018-08-05 version 1.0

240 | ----------------------

241 |

242 | - Initial release

243 |

--------------------------------------------------------------------------------

/LICENSE:

--------------------------------------------------------------------------------

1 | Precise Simulation Limited Software License Agreement

2 |

3 | CAREFULLY READ THE FOLLOWING TERMS AND CONDITIONS ("TERMS") BEFORE

4 | INSTALLING OR USING THE PROGRAMS OR DOCUMENTATION. INSTALLING OR USING

5 | THE PROGRAMS MEANS YOU HAVE ACCEPTED AND AGREE TO BE BOUND BY THE

6 | TERMS AND CONDITIONS OF THIS AGREEMENT. IF YOU DO NOT ACCEPT THEM,

7 | UNINSTALL, REMOVE AND COMPLETELY DELETE THE PROGRAMS AND

8 | DOCUMENTATION.

9 |

10 | 1. Preamble: This Agreement governs the relationship between the

11 | Licensee ("you", "your") and Licensor Precise Simulation Limited

12 | ("we", "us", "ours"). This Agreement sets the terms, rights,

13 | restrictions and obligations on using the FEATool and/or CFDTool

14 | ("Software", "Program(s)") and documentation ("Documentation")

15 | created and owned by Licensor, as detailed herein.

16 |

17 | 2. License Grant: Licensor hereby grants Licensee a Non-assignable &

18 | Non-transferable, Non-exclusive license to run and use the Program,

19 | without the rights to create derivative works, all with accordance

20 | with the terms set forth and other legal restrictions set forth in 3rd

21 | party software used while running Software.

22 |

23 | 2.1 Programs: You may license a specified single installation license

24 | ("SUL"), multi-user/floating network license ("MUL"), or ("CKL") class

25 | kit license under this Agreement, and your license rights are for the

26 | number of installations and users set forth on the purchase order,

27 | agreement, or issued invoice. A free limited and restricted license

28 | ("FREE/TRIAL") is granted for personal, non-commercial use for

29 | evaluation purposes.

30 |

31 | a. the FREE/TRIAL license option is restricted to personal, trial, and

32 | non-commercial use allowing for a single installation and concurrent

33 | use of the Program. You may NOT use the Program with a FREE/TRIAL

34 | license for any commercial, or production use, i.e., you may only use

35 | the Program for experimental, personal, and trial use (to test the

36 | Program). Specifically, the restrictions of the FREE/TRIAL license

37 | Program and Software may not be circumvented in any way without

38 | Payment for an upgraded license.

39 |

40 | b. the specified single installation license SUL must be installed on

41 | a specified computer system and its use is limited to a single

42 | concurrent instance. To change system a system transfer fee may be

43 | required.

44 |

45 | c. the multi-use license option MUL may be installed on a single

46 | networked system or server, or several systems and run concurrently

47 | the number of instances specified in the purchase order, agreement, or

48 | issued invoice.

49 |

50 | d. academic granting institutions with the class kit license CKL

51 | option may install and use the Software in a computer lab/systems

52 | belonging to the institute/institution and run concurrently the number

53 | of instances specified in the purchase order, agreement, or issued

54 | invoice.

55 |

56 | e. regardless of which license you have, you shall use the Programs

57 | only for your internal operations. For the purposes of this Agreement,

58 | "internal operations" means use of the Programs by your employees or

59 | those of your subsidiaries or parent company and for the performance

60 | of consulting or research for third parties who engage you as an

61 | employee or independent contractor. You also shall not disclose any

62 | characteristics or technical capabilities of the Programs to any third

63 | party without our prior written authorization.

64 |

65 | 2.2 Delivery: We may deliver the Programs and Documentation to you in

66 | archival form over the Internet with a passcode or license key which

67 | specifies the licensed Programs. You shall be responsible for all use

68 | of your passcode, authorized or not, and you shall not disclose the

69 | archive passcode or allow it to be used except for installation of the

70 | Programs.

71 |

72 | 2.3 Ownership: All right, title and interest in and to the licensed

73 | Program(s), including without limitation, trade secrets and

74 | copyrights, are, and shall at all times remain, the exclusive property

75 | of us and you shall have no right, therein, except the expressly

76 | limited license rights granted herein.

77 |

78 | 2.4. Non Assignable & Non-Transferable: Licensee may not assign or

79 | transfer his rights and duties under this license.

80 |

81 | 2.5. The Software and Documentation are for your personal use and/or

82 | internal business operations and are not for resale or other transfer

83 | or disposition to any other person or entity. In addition, you

84 | specifically agree not to:

85 |

86 | a. reverse engineer, decompile, disassemble, translate, modify, alter

87 | or otherwise change the Licensor's Software or any part thereof;

88 |

89 | b. attempt to derive the source code, design or structure of the

90 | Licensor's Software;

91 |

92 | c. sell, rent, lease, distribute, assign, sub-license, convey,

93 | transfer, pledge as security or otherwise encumber or transfer

94 | (including by loan or gift) the rights and licenses granted hereunder;

95 |

96 | d. copy, distribute (fork), or reproduce any part of the Software or

97 | Documentation other than as allowed under this Agreement;

98 |

99 | e. use the Software or Documentation in any manner that violates any

100 | statute, law, rule, regulation, directive, guideline, bylaw whether

101 | presently in force or may be implemented by state or local

102 | authorities.

103 |

104 | 3. Term & Termination: The Term of this license shall be until

105 | terminated, or until specified by issued purchase order, agreement, or

106 | issued invoice. Licensor may terminate this Agreement, including

107 | Licensee's license in the case where Licensee:

108 |

109 | a. became insolvent or otherwise entered into any liquidation process; or

110 |

111 | b. Licensee was in breach of any of this license's terms and

112 | conditions and such breach was not cured, immediately upon

113 | notification; or

114 |

115 | c. Licensee otherwise entered into any arrangement which caused

116 | Licensor to be unable to enforce his rights under this License.

117 |

118 | 4. Payment: In consideration of the License granted under clause 2,

119 | Licensee shall pay Licensor a fee which Licensor may deem

120 | adequate. Failure to perform payment shall construe as material breach

121 | of this Agreement. You shall be liable for any taxes (except those on

122 | our net income) due in connection with this Agreement.

123 |

124 | 4.1 No purchase order or any other standardized business form issued

125 | by you, and even if such purchase order or other standardized business

126 | form provides that it takes precedence over any other agreement

127 | between the parties, shall be effective to contradict, modify, add to

128 | or delete from the terms of this Agreement in any manner

129 | whatsoever. Any acknowledgment, in any form, of any such purchase

130 | order or standardized business form is not recognized as a subsequent

131 | writing and will not act as acceptance of such terms.

132 |

133 | 5. Upgrades, Updates and Fixes: Licensor may provide Licensee, from

134 | time to time, with Upgrades, Updates or Fixes, as detailed herein and

135 | according to his sole discretion. Licensee hereby warrants to keep The

136 | Software up-to-date and install all relevant updates and fixes, and

137 | may, at his sole discretion, purchase upgrades, according to the rates

138 | set by Licensor. Licensor shall provide any update or Fix free of

139 | charge; however, nothing in this Agreement shall require Licensor to

140 | provide Updates or Fixes.

141 |

142 | 6. Support: The Software is provided under an AS-IS basis and without

143 | any support, updates or maintenance. Nothing in this Agreement shall

144 | require Licensor to provide Licensee with support or fixes to any bug,

145 | failure, mis-performance or other defect in The Software.

146 |

147 | 7. Feedback: If you choose to provide input and suggestions regarding

148 | problems with or proposed modifications or improvements to the

149 | Programs and Services (“Feedback”) then you hereby grant to us an

150 | unrestricted, perpetual, irrevocable, non-exclusive, fully-paid,

151 | royalty-free right to use the Feedback in any manner and for any

152 | purpose, including to improve the Programs and Services and create

153 | other products and services.

154 |

155 | 8. Trademarks: You grant us permission to include your name, logos,

156 | and trademarks in our promotional and marketing materials and

157 | communications.

158 |

159 | 9. Liability: To the extent permitted under Law, The Software is

160 | provided under an AS-IS basis. Licensor shall never, and without any

161 | limit, be liable for any damage, cost, expense or any other payment

162 | incurred by Licensee as a result of Software's actions, failure, bugs

163 | and/or any other interaction between The Software and Licensee's

164 | end-equipment, computers, other software or any 3rd party,

165 | end-equipment, computer or services. Moreover, Licensor shall never

166 | be liable for any defect in source code written by Licensee when

167 | relying on The Software or using The Software's source code.

168 |

169 | 10. Warranty: The Software is provided without any warranty; Licensor

170 | hereby disclaims any warranty that The Software shall be error free,

171 | without defects or code which may cause damage to Licensee's computers

172 | or to Licensee, and that Software shall be functional. Licensee shall

173 | be solely liable to any damage, defect or loss incurred as a result of

174 | operating software and undertake the risks contained in running The

175 | Software on License's Computer System(s) and Server(s).

176 |

177 | 10.1 Prior Inspection: Licensee hereby states that he inspected The

178 | Software thoroughly and found it satisfactory and adequate to his

179 | needs, that it does not interfere with his regular operation and that

180 | it does meet the standards and scope of his computer systems and

181 | architecture. Licensee found that The Software interacts with his

182 | development, website and server environment and that it does not

183 | infringe any of End User License Agreement of any software Licensee

184 | may use in performing his services. Licensee hereby waives any claims

185 | regarding The Software's incompatibility, performance, results and

186 | features, and warrants that he inspected the The Software.

187 |

188 | 11. No Refunds: Licensee warrants that he inspected The Software

189 | according to clause 8.1 and that it is adequate to his

190 | needs. Accordingly in the case of NON-FREE licenses, as The Software

191 | is intangible goods, Licensee shall not be, ever, entitled to any

192 | refund, rebate, compensation or restitution for any reason whatsoever,

193 | even if The Software contains material flaws.

194 |

195 | 12. Technical Information. You agree that We may collect or process

196 | technical and related information arising from Your use of the

197 | Software which may include but may not be limited to internet protocol

198 | address, hardware identification, operating system, application

199 | software, peripheral hardware, debugging information, and

200 | non-personally identifiable software usage statistics to facilitate

201 | the provisioning of Updates, Support, invoicing or online services,

202 | identify trends and bugs, collect activation information, usage

203 | statistics and track other data related to Your use of the Software.

204 |

205 | 13. Indemnification: Licensee hereby warrants to hold Licensor

206 | harmless and indemnify Licensor for any lawsuit brought against it in

207 | regards to Licensee's use of The Software in means that violate,

208 | breach or otherwise circumvent this license, Licensor's intellectual

209 | property rights or Licensor's title in The Software. Licensor shall

210 | promptly notify Licensee in case of such legal action and request

211 | Licensee's consent prior to any settlement in relation to such lawsuit

212 | or claim.

213 |

214 | 14. Governing Law, Jurisdiction: Licensee hereby agrees not to

215 | initiate class-action lawsuits against Licensor in relation to this

216 | license and to compensate Licensor for any legal fees, cost or

217 | attorney fees should any claim brought by Licensee against Licensor be

218 | denied, in part or in full.

219 |

220 | 15. Revised Terms of Use: We may revise the terms of use of the

221 | Programs from time to time. Revisions are effective upon receipt of

222 | notice from us.

223 |

--------------------------------------------------------------------------------

/README.md:

--------------------------------------------------------------------------------

1 | CFDTool - _CFD Simulation Made Easy_

2 | ====================================

3 |

4 |

5 |

6 | About

7 | -----

8 |

9 | [**CFDTool**](https://www.cfdtool.com) is a

10 | [Computational Fluid Dynamics (CFD)](https://en.wikipedia.org/wiki/Computational_fluid_dynamics)

11 | Toolbox for modeling and simulation of fluid flows with coupled

12 | heat transfer.

13 |

14 | Based on the [FEATool Multiphysics](https://www.featool.com)

15 | simulation platform, _CFDTool_ is specifically designed to make fluid

16 | dynamics and heat transfer simulations easy and fun.

17 |

18 |

19 | Features

20 | --------

21 |

22 | The _CFDTool_ toolbox includes the following features:

23 |

24 | - Completely stand-alone and self-contained toolbox

25 | - Fully integrated and easy to use Graphical User Interface (GUI)

26 | - Modeling and simulation in 1D, 2D, 3D, and axisymmetric coordinate systems

27 | - Seamless [OpenFOAM GUI](https://www.featool.com/Easy-to-Use-OpenFOAM-GUI/) and

28 | [SU2](https://www.featool.com/doc/su2.html) CFD solver integrations

29 | - Built-in geometry and CAD tools

30 | - Automatic mesh and grid generation

31 | - Pre-defined equations and boundary conditions:

32 | + Incompressible viscous fluid flows (Navier-Stokes equations)

33 | + Compressible inviscid flows (Euler equations)

34 | + Heat transfer (Convection and Conduction)

35 | - Multiphysics support for fluid flow and thermal analysis

36 | - Simulation of laminar and turbulent flows (Spalart-Allmaras,

37 | k-epsilon, and k-omega turbulence models available with OpenFOAM/SU2)

38 | - Stationary and time-dependent analysis types

39 | - Postprocessing and visualization

40 |

41 |

42 | [System Requirements](https://www.featool.com/doc/quickstart.html#prereq)

43 | -------------------

44 |

45 | _CFDTool_ is a fully integrated simulation environment, which has been

46 | tested and verified to work with 64-bit Windows, Linux, and MacOS

47 | operating systems with a minimum of 4 GB RAM memory.

48 |

49 |

50 | [Installation](https://www.featool.com/doc/quickstart.html#install)

51 | ------------

52 |

53 | In order to use _CFDTool_, the software must first be installed on the

54 | intended computer system. It is recommended to first uninstall

55 | previous versions before installing/upgrading to a newer version.

56 |

57 | Please follow the steps below to install _CFDTool_ as a stand-alone

58 | app, or as a MATLAB® toolbox. The installers can be downloaded

59 | directly from the

60 | [CFDTool releases](https://github.com/precise-simulation/cfdtool/releases/latest)

61 | and installed manually, or installed from the MATLAB® APPS and Add-On

62 | Toolbar as a toolbox.

63 |

64 |

65 |

66 |  67 |

68 |

67 |

68 |

69 |

70 |

71 | ### Stand-Alone App Installation

72 |

73 | Use the steps below to install the app in stand-alone mode

74 |

75 | 1) First download the installer for your operating system

76 |

77 | + [**CFDTool Windows Installer**](https://github.com/precise-simulation/cfdtool/releases/latest/download/CFDTool_install.exe)

78 |

79 | + [**CFDTool Linux Installer**](https://github.com/precise-simulation/cfdtool/releases/latest/download/CFDTool.install)

80 |

81 | 2) Save it to a directory and run the installer. This will first

82 | download and/or install the application runtime if required (which may

83 | require up to 10 GB space to install), and then the program file will

84 | be extracted.

85 |

86 | 3) When everything has been installed, run the program file to start

87 | _CFDTool_. Please be patient as the application runtime can take some

88 | time to start.

89 |

90 |

91 | ### MATLAB® Toolbox Installation

92 |

93 | Follow the steps below to install _FEATool_ as a MATLAB® toolbox, and

94 | to enable running MATLAB® simulation m-scripts

95 |

96 | 1) Download the

97 | [CFDTool.mlappinstall](https://github.com/precise-simulation/cfdtool/releases/latest/download/CFDTool.mlappinstall)

98 | toolbox installation file.

99 |

100 | 2) Then start MATLAB®, press the **APPS** toolbar button,

101 | and select the **Install App** button.

102 |

103 | 3) When prompted to choose a toolbox file to install, select the

104 | **CFDTool.mlappinstall** file and press **OK**.

105 |

106 | 4) Press the **Install** button if prompted to _"Install to My Apps"_.

107 |

108 |

109 |

110 | Once the toolbox has been installed, an app icon will be available in

111 | the _APPS_ toolbar to start the _CFDTool_ GUI. (Note that MATLAB® may

112 | not show or give any indication of the toolbox installation progress

113 | or completion.)

114 |

115 |

116 | [OpenFOAM® CFD Solver](https://featool.com/doc/openfoam.html)

117 | --------------------

118 |

119 | The optional OpenFOAM CFD solver integration makes it easy to perform

120 | both laminar and turbulent high performance CFD simulations. OpenFOAM

121 | CFD simulations often results in a magnitude or more speedup for

122 | instationary simulations compared to the built-in flow

123 | solvers. Additionally, with the multi-simulation solver integration in

124 | _CFDTool_ it is possible to compare and better validate simulation

125 | results obtained using both the built-in and OpenFOAM CFD solvers.

126 |

127 | The OpenFOAM solver binaries are currently not included with _CFDTool_

128 | and must be installed separately. The OpenFOAM solver integration has

129 | been verified with OpenFOAM versions 2021 and 9. For Microsoft Windows

130 | systems it is recommended to install and use the pre-compiled

131 | Native-windows/mingw binaries available from

132 | [OpenCFD ESI](https://develop.openfoam.com/Development/openfoam/-/wikis/precompiled/windows),

133 | or the distribution from the

134 | [OpenFOAM Foundation](https://openfoam.org/download)

135 | for Linux and MacOS systems.

136 |

137 |

138 | Basic Use

139 | ---------

140 |

141 | _CFDTool_ and its GUI has been specifically designed to be as easy to

142 | use as possible, and making learning CFD simulation by experimentation

143 | easy.

144 |

145 | The modeling process is divided into six different steps or modes

146 |

147 | - **Geometry** - Definition of the geometry to be modeled

148 | - **Grid** - Subdivision of the geometry into smaller cells suitable

149 | for computation

150 | - **Equation** - Specification of material parameters and coefficients

151 | - **Boundary** - Boundary conditions specify how the model interacts

152 | with the surrounding environment (outside the geometry)

153 | - **Solve** - Solution and simulation of the defined model problem

154 | - **Post** - Visualization and postprocessing

155 |

156 | These modes can be accessed by clicking on the corresponding buttons

157 | in left hand side _Mode_ toolbar. The different modes may have

158 | specialized and different _Tools_ available in the corresponding

159 | toolbar. Advanced mode options may also be available in the

160 | corresponding menus.

161 |

162 | A number of pre-defined fluid flow and heat transfer tutorial examples

163 | are available under the **File** > **Model Examples and Tutorials...**

164 | menu option.

165 |

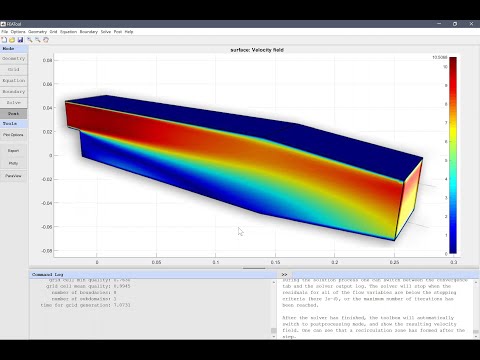

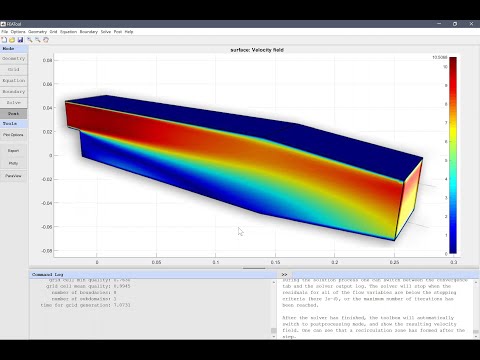

166 | Basic use and how to set up and model turbulent flow past a

167 | backwards facing step with OpenFOAM is explained in the

168 | [linked video tutorial](https://youtu.be/gHGttc31xj0)

169 | (click on the image below to start the tutorial).

170 |

171 |

172 |

173 |  175 |

176 |

175 |

176 |

177 |

178 |

179 | Documentation

180 | -------------

181 |

182 | The _FEATool_

183 | [documentation](https://www.featool.com/doc),

184 | which shares most functionality with _CFDTool_, is available online,

185 | and also by selecting the corresponding option in the _Help_ menu of

186 | the _CFDTool_ GUI.

187 |

188 |

189 | License

190 | -------

191 |

192 | (C) Copyright 2013-2025 by Precise Simulation Limited.

193 | All Rights Reserved.

194 |

195 | CFDTool™ and FEATool Multiphysics™ are trademarks of Precise

196 | Simulation Limited. MATLAB® is a registered trademark of The

197 | MathWorks, Inc. OPENFOAM® is a registered trade mark of OpenCFD

198 | Limited. All other trademarks are the property of their respective

199 | owners. Precise Simulation Ltd and its products are not affiliated

200 | with, endorsed by, sponsored by these trademark owners.

201 |

202 | The license agreement for using CFDTool™ is included with the

203 | distribution and can also be accessed from the _Help_ menu in the

204 | application.

205 |

206 | Carefully read the license terms and conditions before installing or

207 | using the programs or documentation. Installing or using the programs

208 | means you have accepted and agree to be bound by the terms and

209 | conditions of this agreement. if you do not accept them, uninstall,

210 | remove and completely delete the programs and documentation.

211 |

--------------------------------------------------------------------------------

/THIRDPARTY:

--------------------------------------------------------------------------------

https://raw.githubusercontent.com/precise-simulation/cfdtool/fcb49b56030975c3609fedf0c7455b5f461104c0/THIRDPARTY

--------------------------------------------------------------------------------

/cfdtool.m:

--------------------------------------------------------------------------------

1 | %Start CFDTool.

2 | %

3 | % This command starts the main application GUI. The toolbox can

4 | %

5 | %

6 | % cfdtool test % Run all test suites

7 | % cfdtool testt % Run tests for GUI tutorials

8 | %

9 | %

10 | % and optionally with a vector specifying which tests to run

11 | %

12 | % cfdtool test/testt [#] % Run selected tests for test suite

13 | %

14 | % To automatically load a model file or (.fes) script on startup use

15 | %

16 | % cfdtool filename % Start GUI and load model

17 | %

18 | % Furthermore, the following maintenance tasks can also be performed

19 | %

20 | % cfdtool activate % Activate product license

21 | % cfdtool deactivate % Release/free activated license

22 | % cfdtool sysinfo % Print system information

23 |

24 | % Copyright 2013-2025 Precise Simulation, Ltd.

--------------------------------------------------------------------------------

/download.png:

--------------------------------------------------------------------------------

https://raw.githubusercontent.com/precise-simulation/cfdtool/fcb49b56030975c3609fedf0c7455b5f461104c0/download.png

--------------------------------------------------------------------------------

/screenshot.jpg:

--------------------------------------------------------------------------------

https://raw.githubusercontent.com/precise-simulation/cfdtool/fcb49b56030975c3609fedf0c7455b5f461104c0/screenshot.jpg

--------------------------------------------------------------------------------

/tutorials/01_Quickstart/02_heat_exchanger1.fes:

--------------------------------------------------------------------------------

1 | {"meta":{"app":"CFDTool","author":"Precise Simulation","build":"1.9.1","date":"17-Jan-2019","descr":["This heat exchanger example illustrates multiphysics modeling capabilities of CFDTool. The model consists of a series of heated pipes surrounded by a fluid at a lower temperature, and features effects of both free and forced convection. Two types of physical phenomena are considered, fluid flow which is modeled by the Navier-Stokes equations, and heat transfer modeled by a convection and conduction transport equation for the temperature. This system features a two-way multiphysics coupling, the fluid is coupled to and transports the temperature field, and the temperature is also coupled back to the fluid via the Boussinesq approximation accounting for buoyancy effects.","","Due to symmetry one can simplify the full geometry and only study a two dimensional slice between the heated pipes. The geometry will therefore consist of a _0.0075_ by _0.05 m_ rectangle from which a half circle with radius _0.003 m_ centered at _(0, 0.02)_ is removed. The mechanism for heating the pipes is not taken in consideration and are thus assumed to be at a fixed temperature of _Th = 330 K_. A cooling fluid flows from the bottom to the top and has an inlet temperature of _Tc = 300 K_. The other fluid and material parameters can be found in the model tutorial."],"dim":2,"image":"heat_exchanger1.jpg","keyw":["quickstart","heat_exchanger"],"mlver":"R2019a","name":"heat_exchanger1","phys":["Heat Transfer","Navier-Stokes Equations"],"system":"","time":737442,"title":"Heat Exchanger","type":"Multiphysics","user":"precsim","ver":[1,9,1]},

2 | "fields":["type","id","ui_arg","fcn_type","fcn_oarg"],

3 | "data":[

4 | ["introdlg","02_heat_exchanger1.fes",""],

5 | ["overlay",["Quickstart Tutorial","Natural and Forced Convection in a Heat Exchanger"],""],

6 | ["overlay",["","This heat exchanger model consists of a low temperature coolant flowing around a series of heated pipes. The multiphysics simulation involves both natural convection, through buoyancy effects, as well as forced convection, by coupling transport of the temperature field with the fluid flow."],""],

7 | ["msgbox","This tutorial can be run by selecting , **Model Examples and Tutorials...** >, **Quickstart** >, **Heat Exchanger** , from the **File** menu, and followed with the step-by-step instructions in the _User'susers Guide_.",""],

8 | ["pause","","2"],

9 | ["introdlg","close",""],

10 | ["uipushtool","Standard.NewFigure",[],"ClickedCallback",[]],

11 | ["uicontrol","radio_2d",0,"Callback",[]],

12 | ["uitext",[],"Select the **Navier-Stokes Equations** physics mode from the _Select Physics_ drop-down menu. An additional physics mode will be added later to couple and model heat transfer effects."],

13 | ["uicontrol*","popup_physsel",["Navier-Stokes Equations"],"Callback",[]],

14 | ["imgcap"],

15 | ["uicontrol","button_dlgnew_ok",[],"Callback",[]],

16 | ["overlay",["Geometry Mode",""],1],

17 | ["uitext*",[],"Only the fluid surrounding the heat exchanger will be modeled. And by using all symmetry planes, the geometry can be simplified to a two-dimensional planar cross section, which can be constructed by making a rectangle from which a circle is subtracted."],

18 | ["uicontrol","button_rectangle",[],"Callback",[0,1,0,1,"R1"]],

19 | ["uitext",[],"The geometry object properties must now be edited to set the correct size and position of the rectangle. To do this, click on the rectangle **R1** to select it, which also highlights it in red. Then click on the **Inspect/edit selected geometry object** _Toolbar_ button, and change the _min_ and _max_ coordinates of the rectangle, so they span between `0` and `0.0075` in the x-direction, and `0` and `0.05` in the y-direction."],

20 | ["uicontrol*","list_select_gobj",["R1"],"Callback",[]],

21 | ["imgcap"],

22 | ["uicontrol*","button_edit_gobj",[],"Callback",[]],

23 | ["uicontrol*","edit_x_min","0","Callback",[]],

24 | ["uicontrol*","edit_x_max","0.0075","Callback",[]],

25 | ["uicontrol*","edit_y_min","0","Callback",[]],

26 | ["uicontrol*","edit_y_max","0.05","Callback",[]],

27 | ["imgcap"],

28 | ["uicontrol*","button_dlggobj_ok",[],"Callback",[]],

29 | ["uitext",[],"Create a circle with center at _(0, 0.02)_, and radius equal to _0.003_."],

30 | ["uimenu",["Geometry","Create Object...","Circle"],[],"Callback",[]],

31 | ["uicontrol","edit_center","0 0.02","Callback",[]],

32 | ["uicontrol","edit_radius","0.003","Callback",[]],

33 | ["imgcap"],

34 | ["uicontrol","button_dlggobj_ok",{},"Callback",{}],

35 | ["uitext",[],"To subtract the circle from the rectangle, first select both geometry objects by clicking on them, so that both are highlighted in red, and then click on the **- / Subtract geometry objects** button. (Alternatively, if the circle is obscured by the rectangle, they can be selected by holding the _Ctrl_ key, while clicking on the labels **R1** and **C1** in the Selection list box, or in this case simply pressing _Ctrl + A_ to select all objects)."],

36 | ["uicontrol*","list_select_gobj",["R1","C1"],"Callback",[]],

37 | ["uicontrol*","button_subtract_gobj",[],"Callback",[]],

38 | ["imgcap"],

39 | ["uicontrol","button_grid_mode",1,"Callback",[]],

40 | ["uitext*",[],"The default grid may be too coarse to ensure an accurate solution. Decreasing the grid size and generating a finer grid can resolve curved boundaries better."],

41 | ["uicontrol","grid_hmax","0.0005"],

42 | ["uitext",[],"Press the **Generate** button to call the automatic grid generation algorithm."],

43 | ["uicontrol*","grid_generate",[],"Callback",[]],

44 | ["imgcap"],

45 | ["uicontrol","button_equation_mode",1,"Callback",[]],

46 | ["uitext",[],"Equation and material coefficients are specified in _Equation/Subdomain_ mode. In the Equation Settings dialog box, enter the following coefficients, `rho` for the density, `mu` for the viscosity, and `alpha*g*rho*(T-Tc)`alpha g rho T minus Tc for the volume and buoyancy force in the y-direction."],

47 | ["uicontrol*","rho_ns","rho","Callback",[]],

48 | ["uicontrol*","miu_ns","mu","Callback",[]],

49 | ["uicontrol*","Fy_ns","alpha*g*rho*(T-Tc)","Callback",[]],

50 | ["imgcap"],

51 | ["uitext",[],"An equation and physics mode for simulation of heat transfer effects must also be added. To access the multiphysics selection and add another physics mode, press the plus **+** tab and select **Heat Transfer** from the _Select Physics_ drop-down menu. Add the selection by pressing the **Add Physics >>>** button."],

52 | ["uicontrol*","tab_+",0,"Callback",[]],

53 | ["uicontrol*","popup_physsel",["Heat Transfer"],"Callback",[]],

54 | ["imgcap"],

55 | ["uicontrol*","button_addphys",[],"Callback",[]],

56 | ["uitext*",[],"Note that each physics mode will have its own tab for _Subdomain and Equation_ settings, as well as _Boundary_ conditions. Moreover, CFDTool works with any unit system, and it is up to the user to use consistent units for geometry dimensions, material, equation, and boundary coefficients."],

57 | ["uitext",[],"In the _Equation Settings_ tab for the heat transfer physics mode (labeled **ht**), set the _density_ to `rho`, _heat capacity_ to `cp`, and _thermal conductivity_ to `k`, respectively. The convective velocities should be coupled from the Navier-Stokes equations physics mode, to do this enter `u` and `v` in the corresponding edit fields (,as these are the default names of the dependent variables for the velocities). Press **OK** to finish with the equation coefficient specifications."],

58 | ["uicontrol*","rho_ht","rho","Callback",[]],

59 | ["uicontrol*","cp_ht","cp","Callback",[]],

60 | ["uicontrol*","k_ht","k","Callback",[]],

61 | ["uicontrol*","u_ht","u","Callback",[]],

62 | ["uicontrol*","v_ht","v","Callback",[]],

63 | ["imgcap"],

64 | ["uicontrol*","button_dlgeqn_ok",[],"Callback",[]],

65 | ["uitext*",[],"The _Model Constants and Expressions_ functionality can be used to define and store convenient expressions which then are available in the point, equation, boundary coefficients, and as postprocessing expressions. Here it is used to define the material and fluid parameters."],

66 | ["uitext",[],["Press the **Constants** _Toolbar_ button, or select the corresponding entry from the _Equation_ menu, and enter the following variables in the _Model Constants and Expressions_ dialog box. Press _Enter_ after the last expression or use the **Add Row** button to expand the expression list.","| Name | Expression |","|---------|------------|","| rho | 22 |","| mu | 2.8e-3 |","| alpha | 0.26e-3 |","| g | 9.81 |","| Tc | 300 |","| vin | 40e-2 |","| k | 0.55 |","| cp | 3.1e3 |","| Th | 330 |"]],

67 | ["uicontrol*","button_const_expr",[],"Callback",[]],

68 | ["uicontrol*","edit_dlgexpr_11","rho","Callback",[]],

69 | ["uicontrol*","edit_dlgexpr_12","22","Callback",[]],

70 | ["uicontrol*","edit_dlgexpr_21","mu","Callback",[]],

71 | ["uicontrol*","edit_dlgexpr_22","2.8e-3","Callback",[]],

72 | ["uicontrol*","edit_dlgexpr_31","alpha","Callback",[]],

73 | ["uicontrol*","edit_dlgexpr_32","0.26e-3","Callback",[]],

74 | ["uicontrol*","edit_dlgexpr_41","g","Callback",[]],

75 | ["uicontrol*","edit_dlgexpr_42","9.81","Callback",[]],

76 | ["uicontrol*","edit_dlgexpr_51","Tc","Callback",[]],

77 | ["uicontrol*","edit_dlgexpr_52","300","Callback",[]],

78 | ["uicontrol*","edit_dlgexpr_61","vin","Callback",[]],

79 | ["uicontrol*","edit_dlgexpr_62","40e-2","Callback",[]],

80 | ["uicontrol*","edit_dlgexpr_71","k","Callback",[]],

81 | ["uicontrol*","edit_dlgexpr_72","0.55","Callback",[]],

82 | ["uicontrol*","edit_dlgexpr_81","cp","Callback",[]],

83 | ["uicontrol*","edit_dlgexpr_82","3.1e3","Callback",[]],

84 | ["uicontrol*","edit_dlgexpr_91","Th","Callback",[]],

85 | ["uicontrol*","edit_dlgexpr_92","330","Callback",[]],

86 | ["imgcap"],

87 | ["uicontrol*","button_dlgexpr_ok",[],"Callback",[]],

88 | ["uicontrol","button_boundary_mode",1,"Callback",[]],

89 | ["uitext*",[],"Boundary conditions are defined in _Boundary Mode_ and describes how the model interacts with the external environment."],

90 | ["uitext",[],"First select the tab labeled **ns**, which allows for specifying boundary conditions for the Navier-Stokes equations physics mode. Then select all vertical boundaries (here **2**, **4**, and **7**, highlighting them in red), and choose **Symmetry/slip** from the drop down box. Switch to the heat transfer physics mode by selecting the **ht** tab, and choose the **Thermal insulation/symmetry** boundary condition."],

91 | ["uicontrol*","list_seldom",["2","4","7"],"Callback",[]],

92 | ["uicontrol*","popup_selbc_ns",["Symmetry/slip"],"Callback",[]],

93 | ["imgcap"],

94 | ["uicontrol*","tab_ht",0,"Callback",[]],

95 | ["uicontrol*","popup_selbc_ht",["Thermal insulation/symmetry"],"Callback",[]],

96 | ["uitext",[],"Continue with the top boundary (number **3**) which is the outflow. Select **Outflow/pressure** for the Navier-Stokes physics mode, and **Convective flux/outflow** for the heat transfer mode."],

97 | ["uicontrol*","list_seldom",["3"],"Callback",[]],

98 | ["uicontrol*","tab_ns",0,"Callback",[]],

99 | ["uicontrol*","popup_selbc_ns",["Outflow/pressure"],"Callback",[]],

100 | ["uitext",[],"The bottom boundary (number **1**) is the inflow and should be prescribed with the constant velocity `vin`v in in the y-direction, by using the **Inlet/velocity** condition. The **Temperature** should here be fixed to the cold/low temperature, `Tc`."],

101 | ["uicontrol*","list_seldom",["1"],"Callback",[]],

102 | ["uicontrol*","popup_selbc_ns",["Inlet/velocity"],"Callback",[]],

103 | ["uicontrol*","edit_bccoef2_ns","vin","Callback",[]],

104 | ["uicontrol*","tab_ht",0,"Callback",[]],

105 | ["uicontrol*","popup_selbc_ht",["Temperature"],"Callback",[]],

106 | ["uicontrol*","edit_bccoef1_ht","Tc","Callback",[]],

107 | ["uitext",[],"Lastly, the boundaries on the cylinder (**5** and **6**) are walls, and should be prescribed with **Wall/no-slip** boundary conditions for the velocity. For the **Temperature** the constant high temperature, `Th`, should be prescribed."],

108 | ["uicontrol*","list_seldom",["5","6"],"Callback",[]],

109 | ["uicontrol*","popup_selbc_ht",["Temperature"],"Callback",[]],

110 | ["uicontrol*","edit_bccoef1_ht","Th","Callback",[]],

111 | ["uicontrol*","tab_ns",0,"Callback",[]],

112 | ["uicontrol*","popup_selbc_ns",["Wall/no-slip"],"Callback",[]],

113 | ["imgcap"],

114 | ["uicontrol*","button_dlgbdr_ok",[],"Callback",[]],

115 | ["overlay",["Solve Mode",""],1],

116 | ["uitext",[],"Now that the problem is fully specified, press the **Solve** _Mode Toolbar_ button to switch to solve mode. Then press the **=** _Tool_ button , with an equals too sign, to call the solver with the default solver settings."],

117 | ["uicontrol*","button_solve_mode",1,"Callback",[]],

118 | ["uicontrol*","button_solve",[],"Callback",[]],

119 | ["overlay",["Postprocessing Mode",""],1],

120 | ["uitext*",[],"From the visualization of the resulting flow field one can see that the flow is accelerated when it passes between the cylinders. To show the temperature field, open the **Plot Options** and postprocessing settings dialog box, and select to plot and visualize the **Temperature, T** as both _surface_ and _contour_ plots."],

121 | ["imgcap"],

122 | ["uicontrol*","button_post_settings",[],"Callback",[]],

123 | ["uicontrol*","post_surf",["Temperature, T"],"Callback",[]],

124 | ["uicontrol*","ffiso",1,"Callback",[]],

125 | ["uicontrol*","post_iso",["Temperature, T"],"Callback",[]],

126 | ["imgcap"],

127 | ["uicontrol*","button_dlgpost_ok",[],"Callback",[]],

128 | ["uitext*",[],"The temperature plot show that the fluid is heated around the hot cylinder and follows the flow upwards."],

129 | ["uitext*",[],"CFDTool also allows for advanced postprocessing such as boundary integration. Integrate the expression _(T-Tc)/w_, T minus T c divided by the width, over the outflow boundary (where _w = 0.0075_ is the width of the domain) to find the change in the mean temperature."],

130 | ["uimenu","Boundary Integration...",[],"Callback",[]],

131 | ["uicontrol","list_seldom",["3"],"Callback",[]],

132 | ["uicontrol","edit_intexpr","(T-Tc)/0.0075","Callback",[]],

133 | ["imgcap"],

134 | ["uitext",[],"Press **OK** or _Apply_ to calculate and show the result of the boundary integration."],

135 | ["uicontrol*","button_dlginteval_ok",[],"Callback",[]],

136 | ["uitext*",[],"From the result one can see that the mean temperature along the outflow boundary has risen by about _1.7_ degrees."],

137 | ["imgcap"],

138 | ["overlay",["","The tutorial is now complete, and the model can be saved as a binary file (_.fea_), exported as a MATLAB _m_-script file, or a GUI playback file (_.fes_)."],""],

139 | ["uivalidate*",[],"pass=0;try,pass=abs(intbdr('T-Tc',fea,3)/0.0075-1.7)/1.7<0.1;catch,end"]

140 | ]}

141 |

--------------------------------------------------------------------------------

/tutorials/01_Quickstart/03_axisymmetric_flow1.fes:

--------------------------------------------------------------------------------

1 | {"meta":{"app":"CFDTool","author":"Precise Simulation","build":"1.4","date":"02-Sep-2019","descr":["This example models fluid flow in a narrowing pipe section. The constriction of the pipe will accelerate the flow according to the venturi effect. As the fluid is assumed to be both incompressible and isothermal the problem is governed by the Navier-Stokes equations.","","An appropriate boundary condition for the symmetry boundary must be chosen. A homogeneous Neumann insulation/symmetry condition is typically employed for scalar equations, but in the case of fluid flow a slip condition preventing any radial velocity while allowing flow in the axial direction is appropriate.","","The geometry of the problem considers a 2:1 constriction with an initial pipe diameter of _d = 2 m_. The inlet velocity is assumed to be uniform _vin = v(z=0) = 1 m/s_ and the fluid has a density of _rho = 1 kg/m^3_ and viscosity _mu = 0.05 kg/ms_. This gives a Reynolds number of _Re = rho*v*d/mu = 40_, which should result in laminar flow with a parabolic outflow profile."],"dim":2.5,"image":"axisymmetric_flow1.jpg","keyw":["quickstart","axisymmetry","fluid_flow","customization","equation_editing","validation"],"mlver":"R2019a","name":"axisymmetric_flow1","phys":["Navier-Stokes Equations"],"system":"","time":737443,"title":"Axisymmetric Fluid Flow","type":"Fluid Dynamics","user":"precsim","ver":[1,4,0]},

2 | "fields":["type","id","ui_arg","fcn_type","fcn_oarg"],

3 | "data":[

4 | ["introdlg","03_axisymmetric_flow1.fes",""],

5 | ["overlay",["Quickstart Tutorial","Axisymmetric Fluid Flow"],""],

6 | ["overlay",["","This example models fluid flow in a narrowing circular pipe section. The constriction of the pipe will accelerate the flow due to the venturi effect. The model also shows how the PDE equations can easily be customized and modified, in this case to accommodate for the transformation to an axisymmetric coordinate system."],""],

7 | ["msgbox","This tutorial can be run by selecting , **Model Examples and Tutorials...** >, **Quickstart** >, **Axisymmetric Fluid Flow** , from the **File** menu, and followed with the step-by-step instructions in the _User'susers Guide_.",""],

8 | ["pause","","2"],

9 | ["introdlg","close",""],

10 | ["uipushtool","Standard.NewFigure",[],"ClickedCallback",[]],

11 | ["uitext",[],"Click on the **Axisymmetry** _Space Dimension_ selection button in the _New Model_ dialog box, and select **Navier-Stokes Equations** from the _Select Physics_ drop-down list. Leave the space dimension and dependent variable names to their default values. Finish the physics selection and close the dialog box by clicking on the **OK** button."],

12 | ["uicontrol","radio_axi",1,"Callback",[]],

13 | ["uicontrol*","popup_physsel",["Navier-Stokes Equations"],"Callback",[]],

14 | ["imgcap"],

15 | ["uicontrol*","button_dlgnew_ok",[],"Callback",[]],

16 | ["overlay",["Geometry Mode",""],1],

17 | ["uitext*",[],"The geometry of the pipe cross section can be created by making _1 x 2_ and _0.5 x 1_two rectangles aligned with the (_r = 0_) symmetry axis, and also a circle with radius _0.5_ centered at (_1, 2_), and finally subtracting the circle from the joined rectangles."],

18 | ["uicontrol","button_rectangle",[],"Callback",[0,1,0,1,"R1"]],

19 | ["uitext",[],"The geometry object properties must now be edited to set the correct size and position of the rectangle. To do this, click on the rectangle **R1** to select it, which also highlights it in red. Then click on the **Inspect/edit selected geometry object** _Toolbar_ button, and change the _min_ and _max_ coordinates of the rectangle so they span between `0` and `1` in the x-direction, and `0` and `2` in the y-direction."],

20 | ["uicontrol*","list_select_gobj",["R1"],"Callback",[]],

21 | ["uicontrol*","button_edit_gobj",[],"Callback",[]],

22 | ["uicontrol*","edit_x_min","0","Callback",[]],

23 | ["uicontrol*","edit_x_max","1","Callback",[]],

24 | ["uicontrol*","edit_y_min","0","Callback",[]],

25 | ["uicontrol*","edit_y_max","2","Callback",[]],

26 | ["imgcap"],

27 | ["uicontrol*","button_dlggobj_ok",[],"Callback",[]],

28 | ["uicontrol*","button_rectangle",[],"Callback",[-0.5,0.5,0.5,1.5,"R2"]],

29 | ["uitext",[],"Similarly, change the _x_min_ and _x_max_ properties of the second rectangle **R2** to `0` and `0.5`, and _y_min_ and _y_max_ to `2` and `3`."],

30 | ["uicontrol*","list_select_gobj",["R2"],"Callback",[]],

31 | ["uicontrol*","button_edit_gobj",[],"Callback",[]],

32 | ["uicontrol*","edit_x_min","0","Callback",[]],

33 | ["uicontrol*","edit_x_max","0.5","Callback",[]],

34 | ["uicontrol*","edit_y_min","2","Callback",[]],

35 | ["uicontrol*","edit_y_max","3","Callback",[]],

36 | ["imgcap"],

37 | ["uicontrol*","button_dlggobj_ok",[],"Callback",[]],

38 | ["uimenu*",["Geometry","Create Object...","Circle"],{},"Callback",{}],

39 | ["uicontrol*","edit_center","1 2","Callback",[]],

40 | ["uicontrol*","edit_radius","0.5","Callback",{}],

41 | ["imgcap"],

42 | ["uicontrol*","button_dlggobj_ok",[],"Callback",[]],

43 | ["imgcap"],

44 | ["uitext",[],"To create the combined geometry, select **Combine Objects...** from the _Geometry_ menu. Enter the formula `R1 + R2 - C1`R1 plus R2 minus C1 in the edit field of the _Combine Geometry Objects_ dialog box and press **OK**."],

45 | ["uimenu*","Combine Objects...",[],"Callback",[]],

46 | ["uicontrol*","edit_dlgedit","R1 + R2 - C1","Callback",[]],

47 | ["imgcap"],

48 | ["uicontrol*","button_dlgedit_ok",[],"Callback",[]],

49 | ["imgcap"],

50 | ["uicontrol","button_grid_mode",1,"Callback",[]],

51 | ["uitext*",[],"The default grid may be too coarse to ensure an accurate solution. Decreasing the grid size and generating a finer grid can resolve curved boundaries better."],

52 | ["uicontrol","grid_hmax","0.1"],

53 | ["uitext",[],"Press the **Generate** button to call the automatic grid generation algorithm."],

54 | ["uicontrol*","grid_generate",[],"Callback",[]],

55 | ["imgcap"],

56 | ["uicontrol","button_equation_mode",1,"Callback",[]],

57 | ["uitext",[],"Equation and material coefficients are specified in _Equation/Subdomain_ mode. In the Equation Settings dialog box enter `1` for the density and `5e-2` for the viscosity."],

58 | ["uitext*",[],"Note that CFDTool can work with any unit system, 4 it 02 Sep to the user to use consistent units for geometry dimensions, material, equation, and boundary coefficients."],

59 | ["uicontrol*","rho_ns","1","Callback",[]],

60 | ["uicontrol*","miu_ns","5e-2","Callback",[]],

61 | ["uitext",[],"Also select the **(P2P1/Q2Q1) second order conforming Stokes element** finite element discretization for higher accuracy, and to avoid having to reformulate the stabilization terms."],

62 | ["uicontrol*","popup_sfun_ns",["(P2P1/Q2Q1) second order conforming Stokes element"],"Callback",[]],

63 | ["imgcap"],

64 | ["uitext",[],"Press **OK** to finish with the equation editing and coefficient specifications."],

65 | ["uicontrol*","button_dlgeqn_ok",[],"Callback",[]],

66 | ["uitext",[],"Switch to boundary condition specification mode by clicking on **Boundary** the _Mode Toolbar_ button. In the _Boundary Settings_ dialog box, first choose all boundaries in the left hand side _Boundaries_ list box and select the **Wall/no-slip** boundary condition from the drop-down menu. Now select the lower inflow boundary (number **1**) in the left hand side Boundaries list box and select the **Inlet/velocity** boundary condition. Enter `1` in the edit field for the velocity _v0_ in the z-direction."],

67 | ["overlay",["Boundary Mode",""],1],

68 | ["uitext*",[],"Boundary conditions are defined in _Boundary Mode_ and describes how the model interacts with the external environment."],

69 | ["uitext",[],"Switch to boundary condition specification mode by clicking on **Boundary** the _Mode Toolbar_ button. In the _Boundary Settings_ dialog box, first choose all boundaries in the left hand side _Boundaries_ list box, and select the **Wall/no-slip** boundary condition from the drop-down menu. Then select the **Inlet/velocity** boundary condition for the lower inflow boundary (number **1**), and enter `1` in the edit field for the velocity _v0_v 0 in the z-direction."],

70 | ["uicontrol*","button_boundary_mode",1,"Callback",[]],

71 | ["uitext*",[],"Boundary conditions are defined in _Boundary Mode_ and describes how the model interacts with the external environment."],

72 | ["uicontrol*","list_seldom",["1"],"Callback",[]],

73 | ["uicontrol*","popup_selbc_ns",["Inlet/velocity"],"Callback",[]],

74 | ["uicontrol*","edit_bccoef2_ns","1","Callback",[]],

75 | ["imgcap"],

76 | ["uitext",[],"Select the top outflow boundary (number **5**) and the **Neutral outflow/stress boundary** condition from the drop-down menu (alternatively, it is also possible prescribe a pressure at the outflow with the _Outflow/pressure_ condition)."],

77 | ["uicontrol*","list_seldom",["5"],"Callback",[]],

78 | ["uicontrol*","popup_selbc_ns",["Neutral outflow/stress boundary"],"Callback",[]],

79 | ["uitext",[],"Lastly, select the left side boundaries on the symmetry axis (number **3** and **6**) and select the **Symmetry/slip** boundary condition from the drop-down menu. This will prevent flow in the radial direction while allowing it in the axial direction. Finish the boundary condition specification by clicking the **OK** button."],

80 | ["uicontrol*","list_seldom",["6","7"],"Callback",[]],

81 | ["uicontrol*","popup_selbc_ns",["Symmetry/slip"],"Callback",[]],

82 | ["imgcap"],

83 | ["uicontrol*","button_dlgbdr_ok",[],"Callback",[]],

84 | ["overlay",["Solve Mode",""],1],

85 | ["uitext",[],"Now that the problem has been defined, press the **Solve** _Mode Toolbar_ button to switch to solve mode, and press the **Settings** button to open the _Solver Settings_ dialog box."],

86 | ["uicontrol*","button_solve_mode",1,"Callback",[]],

87 | ["uicontrol*","button_solver_settings",[],"Callback",[]],

88 | ["uitext",[],"In the _Non-Linear Solver Settings_ section of the Solver Settings dialog box, increase the _Maximum non-linear iterations_ to `100`, and set the _Non-linear relaxation parameter_ to `0.8` to relax the convergence of the solver."],

89 | ["uicontrol*","maxnit","100","Callback",[]],

90 | ["uicontrol*","nlrlx","0.8","Callback",[]],

91 | ["imgcap"],

92 | ["uitext",[],"To start the solver with the chosen settings press the **Solve** button, or press **OK** and then the **=** _Toolbar_ button with an equals too sign."],

93 | ["uicontrol*","button_dlgsolversettings_solve",[],"Callback",[]],

94 | ["imgcap"],

95 | ["overlay",["Postprocessing Mode",""],1],

96 | ["uitext*",[],"After the problem has been solved CFDTool will automatically switch to postprocessing mode and display the computed velocity field, which clearly shows how the flow is significantly accelerated by the pipe constriction."],

97 | ["uitext*",[],"Cross sections of expressions such as the velocity profile can be plotted by using the **Point/Line Evaluation...** feature from the _Post_ menu."],

98 | ["uimenu","Point/Line Evaluation...",[],"Callback",[]],

99 | ["uitext",[],"Enter the evaluation coordinates `0:0.05:0.5`0 to 0.5 in steps of 0.05 and `2.8` in the _r_ and _z-directions_, respectively. These expressions give vectors of coordinates points to evaluate."],

100 | ["uicontrol*","edit_rcoord","0:0.05:0.5","Callback",[]],

101 | ["uicontrol*","edit_zcoord","2.8","Callback",[]],

102 | ["imgcap"],

103 | ["uitext",[],"Press _Apply_ or **OK** to create a new figure with the cross section plot."],

104 | ["uicontrol*","buttons_dlgpntline_ok",[],"Callback",[]],

105 | ["uitext*",[],"From the cross section plot, one can see that the velocity profile close to the outlet, at _z = 2.8_, is starting to shift from parabolic to a more square profile indicating a higher flow rate. This also suggests that one might need to study a longer outflow section to allow for a fully developed parabolic laminar flow profile."],

106 | ["imgcap"],

107 | ["figure*","Line Evaluation",{},"closeRequestFcn",{}],

108 | ["overlay",["","The tutorial is now complete, and the model can be saved as a binary file (_.fea_), exported as a MATLAB _m_-script file, or a GUI playback file (_.fes_)."],""],

109 | ["uivalidate*",[],"pass=0;try,r=linspace(0,1/2,20);z=0.9*3*ones(1,20);U=evalexpr('sqrt(u^2+w^2)',[r;z],fea).';U_ref=8*(1-4*r.^2);pass=sqrt(sum((U-U_ref).^2)/sum(U_ref.^2))<0.15;catch,end"]

110 | ]}

111 |

--------------------------------------------------------------------------------

/tutorials/01_Quickstart/04_natural_convection1.fes:

--------------------------------------------------------------------------------

1 | {"meta":{"app":"CFDTool","author":"Precise Simulation","build":"1.9.1","date":"16-Mar-2019","descr":["This multiphysics model illustrates natural convection effects in a unit square domain using the Boussinesq approximation. The model involves a Navier-Stokes equations physics mode, representing the fluid flow with solid wall or no-slip boundary conditions everywhere. In addition a heat transfer physics mode is added to model the temperature field . The top and bottom boundaries are perfectly insulated while the left boundary is prescribed a unit temperature and the right zero.","","The physics modes are two way coupled through the vertical source term in the Navier-Stokes equations, _Pr*Ra*T_, and the velocities transporting the temperature coming directly from the fluid flow. First, the Prandtl and Rayleigh numbers are set to _Pr = 0.71_ and _Ra = 1e3_, respectively, after which the _Ra_ number will be increased to _1e4_. The references contain benchmark reference and comparison results for a number of quantities such as maximum velocities and the Nusselt number [9,10].","","References:","","[9] D. de Vahl Davis, Natural Convection of Air in a Square Cavity - A Benchmark Solution, Int. J. Numer. Meth. Fluids, vol. 3, pp. 249-264, 1983.","","[10] D. de Vahl Davis and I. P. Jones, Natural Convection of Air in a Square Cavity - A Comparison Exercise, Int. J. Numer. Meth. Fluids, vol. 3, pp. 227-248, 1983."],"dim":2,"image":"natural_convection1.jpg","keyw":["natural_convection","validation"],"mlver":"R2018b","name":"natural_convection1","phys":["Heat Transfer","Navier-Stokes Equations"],"system":"","time":737501,"title":"Natural Convection in a Square Cavity","type":"Multiphysics","user":"precsim","ver":[1,9,1]},

2 | "fields":["type","id","ui_arg","fcn_type","fcn_oarg"],

3 | "data":[

4 | ["uipushtool","Standard.NewFigure",{},"ClickedCallback",{}],

5 | ["uicontrol","popup_physsel",["Navier-Stokes Equations"],"Callback",{}],

6 | ["imgcap"],

7 | ["uicontrol","button_dlgnew_ok",{},"Callback",{}],

8 | ["uimenu",["Geometry","Create Object...","Rectangle"],{},"Callback",{}],

9 | ["uicontrol","button_dlggobj_ok",{},"Callback",{}],

10 | ["uicontrol","button_grid_mode",1,"Callback",{}],

11 | ["uicontrol","grid_hmax","0.03"],

12 | ["uicontrol","grid_generate",{},"Callback",{}],

13 | ["imgcap"],

14 | ["uicontrol","button_equation_mode",1,"Callback",{}],

15 | ["uitext*",[],"The non-dimensionalized form of the Boussinesq source term _Pr*Ra*T_ couples the temperature to the y-direction source term of the Navier-Stokes equations."],

16 | ["uicontrol","Fy_ns","Pr*Ra*T","Callback",{}],

17 | ["imgcap"],

18 | ["uicontrol","tab_+",0,"Callback",{}],

19 | ["uitext*",[],"Add the heat transfer physics mode and coupled the velocities _u_ and _v_ to the convective transport terms."],

20 | ["uicontrol","popup_physsel",["Heat Transfer"],"Callback",{}],

21 | ["imgcap"],

22 | ["uicontrol","button_addphys",{},"Callback",{}],

23 | ["uicontrol","u_ht","u","Callback",{}],

24 | ["uicontrol","v_ht","v","Callback",{}],

25 | ["imgcap"],

26 | ["uicontrol","button_dlgeqn_ok",{},"Callback",{}],

27 | ["uitext",[],["Press the **Constants** _Toolbar_ button, or select the corresponding entry from the _Equation_ menu, and enter the following values for the Prandtl and Rayleigh numbers in the _Model Constants and Expressions_ dialog box.","| Name | Expression |","|------|------------|","| Pr | 0.71 |","| Ra | 1e3 |"]],

28 | ["uicontrol*","button_const_expr",{},"Callback",{}],

29 | ["uicontrol*","edit_dlgexpr_11","Pr","Callback",{}],

30 | ["uicontrol*","edit_dlgexpr_12","0.71","Callback",{}],

31 | ["uicontrol*","edit_dlgexpr_21","Ra","Callback",{}],

32 | ["uicontrol*","edit_dlgexpr_22","1e3","Callback",{}],

33 | ["imgcap"],

34 | ["uicontrol*","button_dlgexpr_ok",{},"Callback",{}],

35 | ["uicontrol","button_boundary_mode",1,"Callback",{}],

36 | ["uitext*",[],"Switch to the **ns** tab, which corresponds to the boundary conditions for the Navier-Stokes equations physics mode. Then select the **Wall/no-slip** for all four boundaries."],

37 | ["uitext*",[],"Click on the **ht** tab to change to specifying boundary conditions for the heat transfer physics mode. Select **Thermal insulation/symmetry** conditions for the top and bottom boundaries."],

38 | ["uicontrol","tab_ht",0,"Callback",{}],

39 | ["uicontrol","list_seldom",["1","3"],"Callback",{}],

40 | ["uitext*",[],"Select a **Temperature** boundary conditions for the left and right boundaries, and set a fixed temperature equal to _1_ at the left side."],

41 | ["uicontrol","popup_selbc_ht",["Thermal insulation/symmetry"],"Callback",{}],

42 | ["imgcap"],

43 | ["uicontrol","list_seldom",["4"],"Callback",{}],

44 | ["uicontrol","popup_selbc_ht",["Temperature"],"Callback",{}],

45 | ["uicontrol","edit_bccoef1_ht","1","Callback",{}],

46 | ["imgcap"],

47 | ["uicontrol","list_seldom",["2"],"Callback",{}],

48 | ["uicontrol","popup_selbc_ht",["Temperature"],"Callback",{}],

49 | ["imgcap"],

50 | ["uicontrol","button_dlgbdr_ok",{},"Callback",{}],

51 | ["uicontrol","button_solve_mode",1,"Callback",{}],

52 | ["uicontrol","button_solve",{},"Callback",{}],

53 | ["uitext*",[],"One can see how the temperature difference is causing a vortex in the flow field, which in turn causes an offset in the temperature field."],

54 | ["imgcap"],

55 | ["uitext*",[],"Change the plot to visualize the temperature field as surface and contour plots, and the velocity field as an arrow plot."],

56 | ["uicontrol","button_post_settings",{},"Callback",{}],

57 | ["uicontrol","ffarrow",1,"Callback",{}],

58 | ["uicontrol","post_surf",["Temperature, T"],"Callback",{}],

59 | ["uicontrol","ffiso",1,"Callback",{}],

60 | ["uicontrol","post_iso",["Temperature, T"],"Callback",{}],

61 | ["imgcap"],

62 | ["uicontrol","button_dlgpost_ok",{},"Callback",{}],

63 | ["imgcap"],

64 | ["uitext*",[],"Use the boundary integration postprocessing tool to calculate the average Nusselt number for the vertical boundaries, and compare it to the reference value of _1.118_."],

65 | ["uimenu",["Post","Boundary Integration..."],{},"Callback",{}],

66 | ["uicontrol","list_seldom",["2","4"],"Callback",{}],

67 | ["uicontrol","edit_intexpr","abs(Tx)/2","Callback",{}],

68 | ["uicontrol","button_dlginteval_apply",{},"Callback",{}],

69 | ["imgcap"],

70 | ["uicontrol","button_dlginteval_ok",{},"Callback",{}],

71 | ["uivalidate",[],"pass=0;try,Nu_mean=abs(intbdr('Tx/2',fea,[2,4],2));pass=abs(Nu_mean-1.118)/1.118<0.06;catch,end"],

72 | ["uitext*",[],"The simulation will now be repeated but with an increased Rayleigh number _Ra = 1e4_. Instead of starting over from the beginning the existing solution will be used as a starting guess which helps with non-linear convergence."],

73 | ["uimenu",["Equation","Model Constants and Expressions..."],{},"Callback",{}],

74 | ["uicontrol","edit_dlgexpr_22","1e4","Callback",{}],

75 | ["imgcap"],

76 | ["uicontrol","button_dlgexpr_ok",{},"Callback",{}],

77 | ["uicontrol","button_solve_mode",1,"Callback",{}],

78 | ["uitext*",[],"To assist with convergence, as well as selecting the old solution as initial value, also increase the non-linear relaxation and the maximum number of non-linear iterations."],

79 | ["uicontrol","button_solver_settings",{},"Callback",{}],

80 | ["uicontrol","init1",1,"Callback",{}],

81 | ["uicontrol","maxnit","100","Callback",{}],

82 | ["uicontrol","nlrlx","0.8","Callback",{}],

83 | ["imgcap"],

84 | ["uicontrol","button_dlgsolversettings_solve",{},"Callback",{}],

85 | ["uitext*",[],"It is evident that the increase in Rayleigh number causes a significantly stronger rotation and stretching of the temperature field."],

86 | ["imgcap"],

87 | ["uitext*",[],"Use boundary integration tool again to calculate the mean Nusselt number for the vertical boundaries, and compare it to the corresponding reference value of _2.243_ for _Ra = 1e4_."],

88 | ["uimenu",["Post","Boundary Integration..."],{},"Callback",{}],

89 | ["uicontrol","list_seldom",["2","4"],"Callback",{}],

90 | ["uicontrol","edit_intexpr","abs(Tx)/2","Callback",{}],

91 | ["uicontrol","button_dlginteval_apply",{},"Callback",{}],

92 | ["imgcap"],

93 | ["uicontrol","button_dlginteval_ok",{},"Callback",{}],

94 | ["uivalidate",[],"pass=0;try,Nu_mean=abs(intbdr('Tx/2',fea,[2,4],2));pass=abs(Nu_mean-2.243)/2.243<0.13;catch,end"]

95 | ]}

96 |

--------------------------------------------------------------------------------

/tutorials/01_Quickstart/axisymmetric_flow1.jpg:

--------------------------------------------------------------------------------

https://raw.githubusercontent.com/precise-simulation/cfdtool/fcb49b56030975c3609fedf0c7455b5f461104c0/tutorials/01_Quickstart/axisymmetric_flow1.jpg

--------------------------------------------------------------------------------

/tutorials/01_Quickstart/heat_exchanger1.jpg:

--------------------------------------------------------------------------------

https://raw.githubusercontent.com/precise-simulation/cfdtool/fcb49b56030975c3609fedf0c7455b5f461104c0/tutorials/01_Quickstart/heat_exchanger1.jpg

--------------------------------------------------------------------------------

/tutorials/01_Quickstart/natural_convection1.jpg:

--------------------------------------------------------------------------------

https://raw.githubusercontent.com/precise-simulation/cfdtool/fcb49b56030975c3609fedf0c7455b5f461104c0/tutorials/01_Quickstart/natural_convection1.jpg

--------------------------------------------------------------------------------

/tutorials/02_Heat_Transfer/01_heat_transfer1.fes:

--------------------------------------------------------------------------------

1 | {"meta":{"app":"CFDTool","author":"Precise Simulation","build":"1.9.1","date":"12-Feb-2019","descr":["Transient heat diffusion problem where a unit length rod is kept at fixed temperature _T = 25_ at the right end and losing heat from a constant outward heat flux _q_n=1_ at the other end. The computed results are compared with the analytic solution",""," Tref = (24+x) + sum(n=1,inf) 8/(1-2*n)^2/pi^2*cos((n-1/2)*pi*x)*exp(-((n-1/2)^2*pi^2)*t)"],"dim":1,"image":"heat_transfer1.jpg","keyw":["heat_diffusion","validation"],"mlver":"R2019a","name":"heat_transfer1","phys":["Heat Transfer"],"system":"","time":737468,"title":"Transient Heat Diffusion in a Rod","type":"Heat Transfer","user":"precsim","ver":[1,9,1]},

2 | "fields":["type","id","ui_arg","fcn_type","fcn_oarg"],

3 | "data":[

4 | ["uipushtool","Standard.NewFigure",[],"ClickedCallback",[]],

5 | ["uicontrol","radio_1d",1,"Callback",[]],

6 | ["uicontrol","popup_physsel",["Heat Transfer"],"Callback",[]],

7 | ["imgcap"],

8 | ["uicontrol","button_dlgnew_ok",[],"Callback",[]],

9 | ["uicontrol","button_line",[],"Callback",[]],

10 | ["uicontrol","button_linegeom_ok",[],"Callback",[]],

11 | ["imgcap"],

12 | ["uicontrol","button_grid_mode",1,"Callback",[]],

13 | ["uicontrol","grid_generate",[],"Callback",[]],

14 | ["imgcap"],

15 | ["uicontrol","button_equation_mode",1,"Callback",[]],

16 | ["uicontrol","eqn_init1_ht","25","Callback",[]],

17 | ["imgcap"],

18 | ["uicontrol","button_dlgeqn_ok",[],"Callback",[]],